API 11AX V11-106 Valve Ball and Valve Seat

Brand Name : JINXIN

Place of Origin : CHINA

Delivery Time : 7-15DAYS

Supply Ability : 10 ton/month

Matierial : Tungsten carbide,tungsten

These balls are primarily used in high-pressure and high-temperature applications, including oil & gas, chemical processing, and fluid control systems.

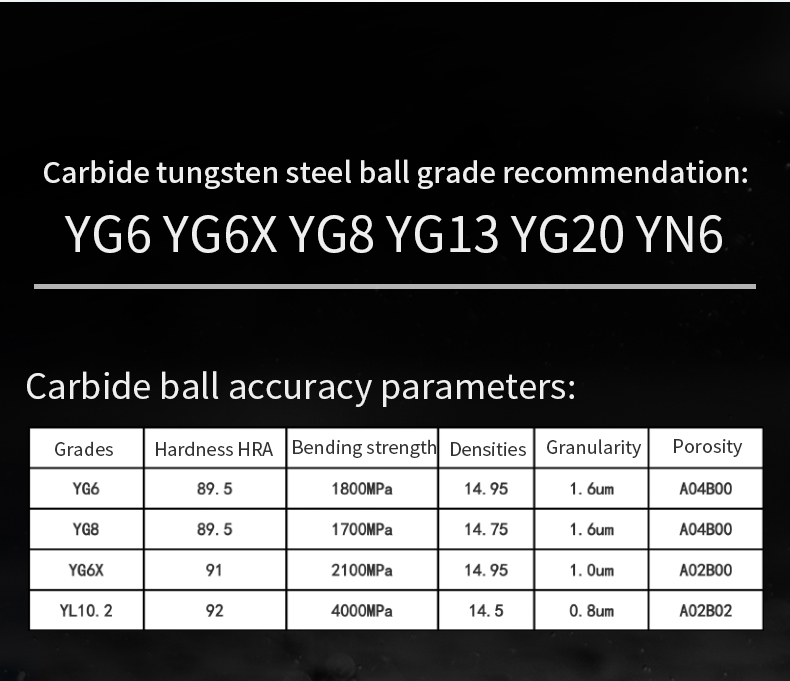

Cemented carbide valve ball description

Carbide valve balls are precision-engineered components made from high-quality tungsten carbide, known for their exceptional hardness, wear resistance, and corrosion resistance. These balls are primarily used in high-pressure and high-temperature applications, including oil & gas, chemical processing, and fluid control systems. With excellent sealing performance and long service life, tungsten carbide valve balls maintain tight shut-off even in abrasive and corrosive environments. Available in various grades and dimensions, they can be customized to meet specific industrial requirements.

What's the Material of our Valve Seat ?

3. Each ball-and-seat combination is vacuum tested to ensure a perfect seal is obtained in all positions of contact.

Cemented carbide valve ball Feature

High precision, high hardness, wear resistance, corrosion resistance, bending resistance, and harsh environment can replace steel balls.

| Tungsten carbide balls | |||||||||

| Type | Q-2.3 | Q-2.5 | Q-2.7 | Q-3.3 | Q-4.2 | Q-5.5 | Q-6 | Q-8 | Q-10 |

| Diameter | 2.3 | 2.5 | 2.7 | 3.3 | 4.2 | 5.5 | 6 | 8 | 10 |

| Tolerance (mm) | ±0.3 | ±0.3 | ±0.4 | ±0.4 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 |

| Type | Q-12 | Q-20 | Q-25 | Q-30 | Q-35 | Q-40 | Q-45 | Q-50 | Q-60 |

| Diameter | 12 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 |

| Tolerance (mm) | ±0.6 | ±0.6 | ±0.6 | ±1.0 | ±1.0 | ±1.2 | ±1.2 | ±1.6 | ±1.6 |

Any interested items please feel free to contact:

Contact:vincent

Mob: +8613357331966

wechat:13357331966

WhatsApp: +8613357331966

Email: jinxin012@ojinxin.com