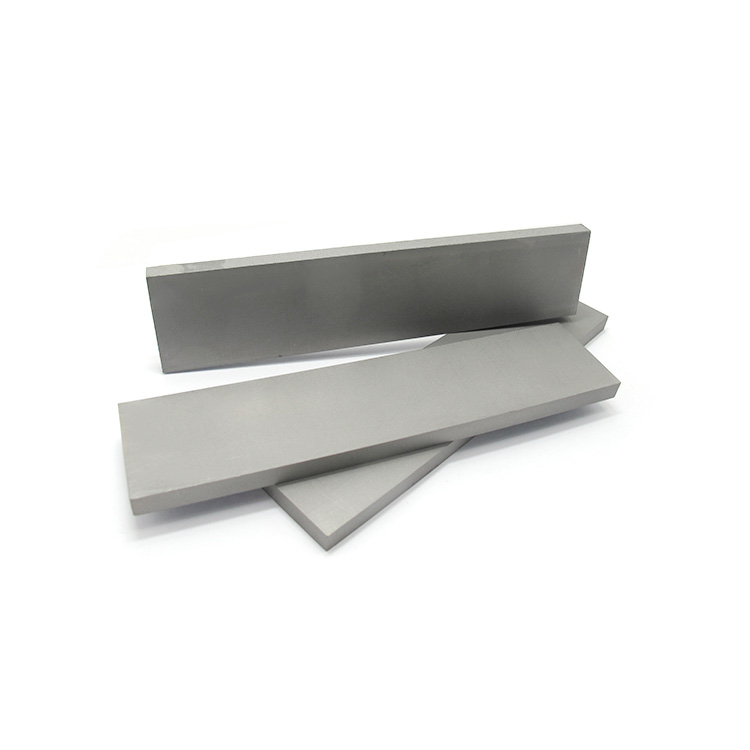

TiN/TiCN Ceramic Carbide Alloy Plates for Knives, Scrapers, and Wear Parts

Brand Name : JX

Place of Origin : zhuzhou

MOQ : low moq

Packaging Details : General Packaging

Delivery Time : 20-25 days

Supply Ability : 30,000–50,000 pcs per month

Matierial : ceramic alloy/TiN/TiCN

Grade : ZT1250,ZT4200,ZT6200,ZT6300.....

Application : cutting tool, wear part

Our ceramic alloy strips are designed for metalworking, tooling fixtures, wear-resistant components, and other demanding industrial applications. Compared with traditional tungsten carbide, ceramic alloy offers a more cost-effective solution while still delivering comparable performance in many working conditions. With mature R&D capability and stable production capacity, we supply various sizes of ceramic alloy strips and support customization for dimensions, tolerances, and material formulas.

Product Introduction

Our ceramic alloy bars (cermet strips) are manufactured with high-purity TiC or TiCN as the main phase and reinforced with metal binders, offering excellent wear resistance, high strength, and outstanding thermal stability. They are widely used for wear-resistant components, cutting tools, forming tools, mining tools, and precision machining applications.

Key Selling Points

High Temperature Resistance

Ensures stable performance under long - term high - heat cutting or friction environments.

Superior Wear Resistance

TiC/TiCN ceramic alloy provides 3–5 times the durability of traditional alloy steel.

Anti - oxidation & Long Lifespan

Greatly extends tool life and reduces replacement frequency.

Low Friction Coefficient

Improves machining smoothness and reduces heat generation.

High Hardness & High Strength

Ideal for wear - resistant parts and metal cutting inserts.

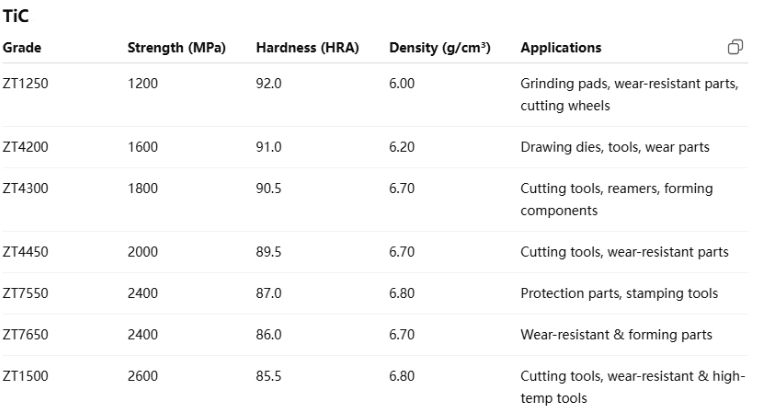

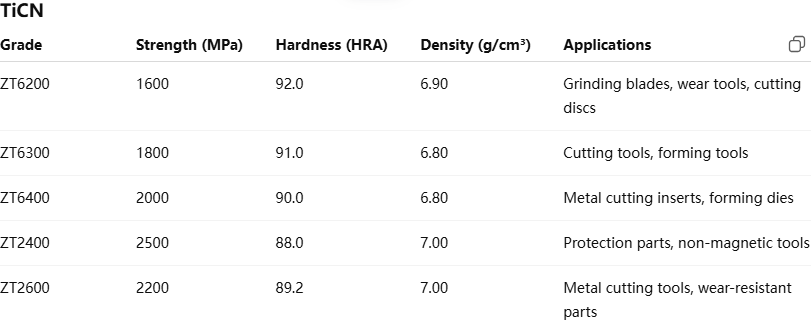

Available Grades

Material Characteristics

Property | Description |

High Temperature Resistance | Can be dry-cut, reduces cost and environmentally friendly |

Oxidation Resistance | Supports high-speed machining, improves productivity |

High Wear Resistance | Wide compatibility for various material machining |

Low Friction Coefficient | Allows smoother machining and better surface finish |

No Coating Required | Convenient and economical for long-term use |

Low Density | Lightweight resource-efficient material |

What We Offer

1.Customized sizes

2.OEM / ODM services

3.Polished or ground surfaces

4.Bulk production capacity

5.Samples available