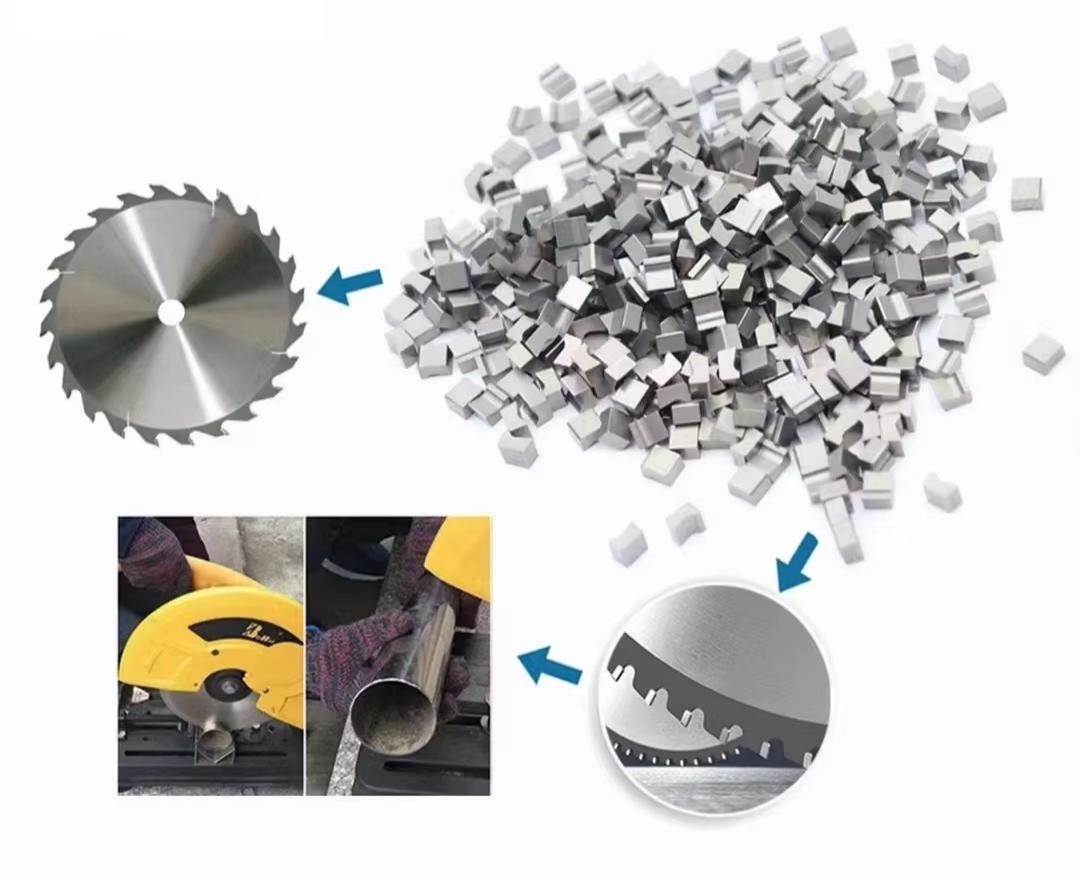

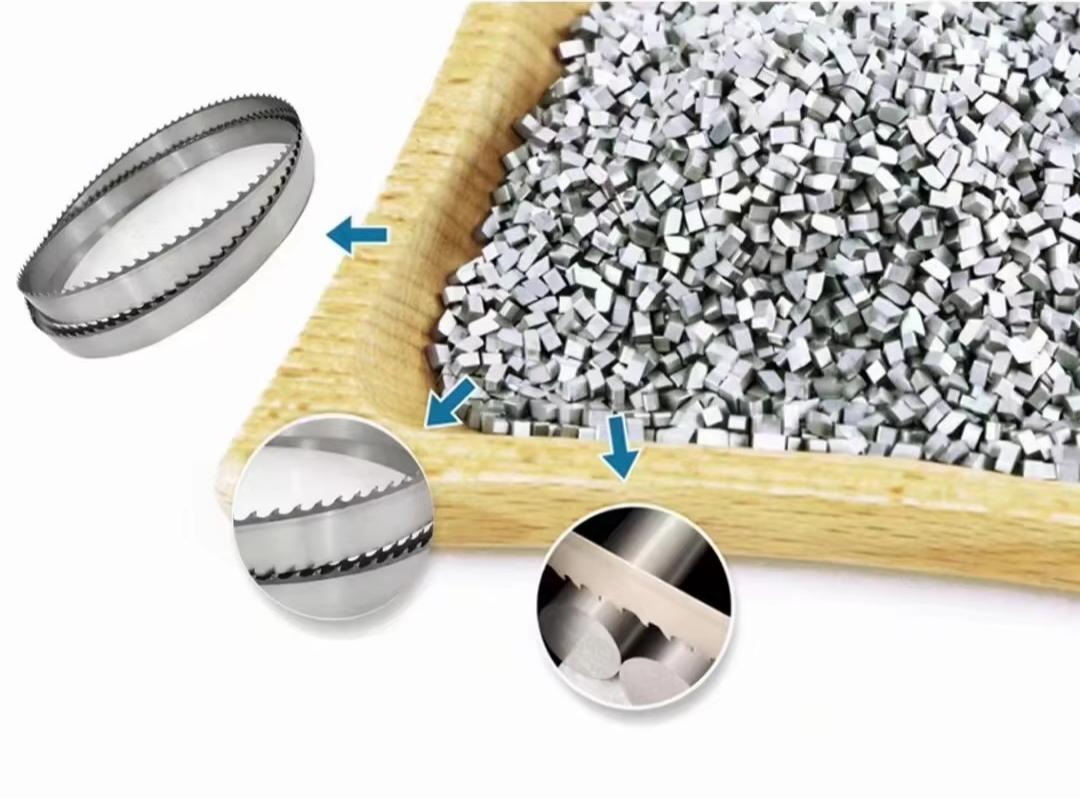

TiC/TiCN Based Cermet Saw Tips for Precision Industrial Sawing Applications

Brand Name : JX

Place of Origin : zhuzhou

MOQ : 200pcs

Packaging Details : General Packaging

Delivery Time : 20-25 days

Supply Ability : 30,000–50,000 pcs per month

Matierial : cermet (TiN/TiCN)

Grade : ZT1250,ZT4200,ZT6200,ZT6300.....

Application : welded on saw blade for cutting

Designed for industrial sawing applications, our cermet saw tips made of TiC/TiCN materials deliver stable cutting performance with lower cost, ideal for high-usage and frequently replaced consumable tools.

Product Overview

TiC/TiCN metal ceramic saw tips, also known as cermet saw tips, are engineered for high-performance industrial cutting applications where stable cutting conditions and superior surface finish are required.

Compared with conventional tungsten carbide saw tips, cermet saw tips offer lower friction, improved thermal stability, and more consistent cutting performance, especially in finishing and continuous cutting operations.

Manufactured through advanced powder metallurgy and precision sintering processes, these saw tips provide excellent wear resistance while maintaining cost efficiency, making them an ideal carbide alternative for saw blade manufacturing.

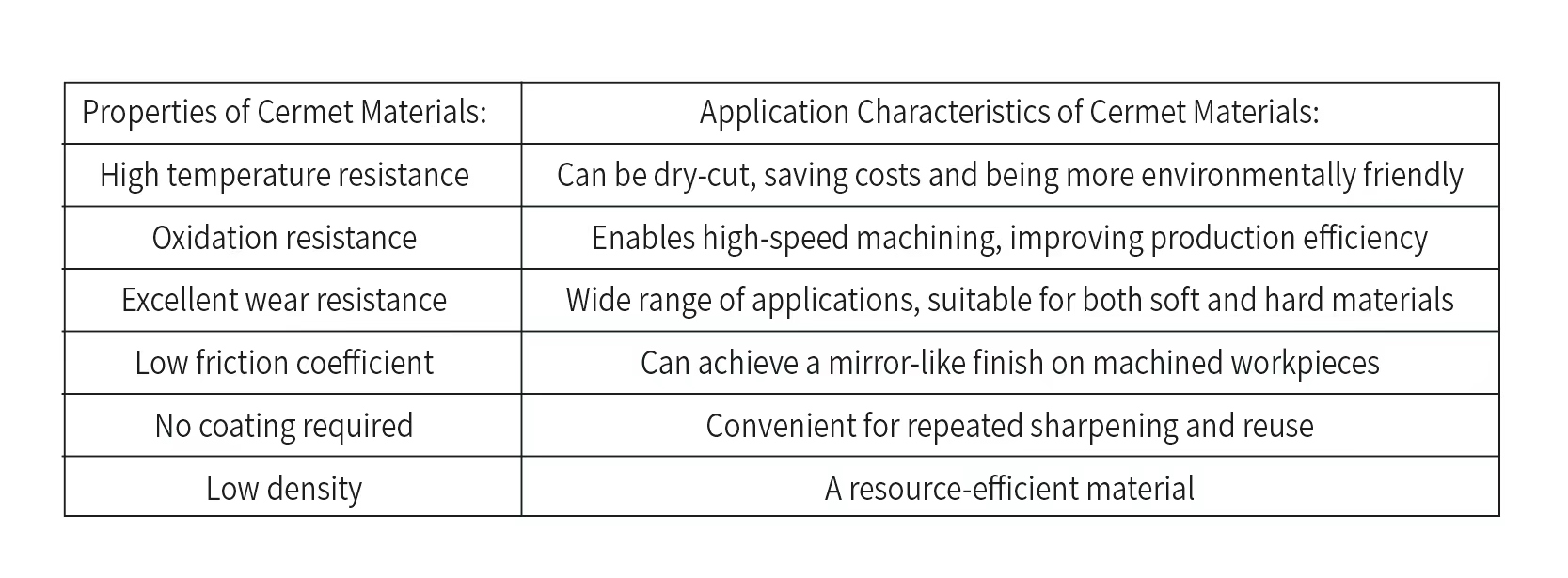

Cermet saw tip Key Features & Advantages

1.TiC / TiCN Metal Ceramic Composition

Optimized TiC and TiCN matrix delivers high hardness, strong oxidation resistance, and excellent thermal stability.

2.Low Friction for Clean Cutting

Reduced cutting resistance results in smoother surface finish and lower heat generation during sawing.

3.Stable Performance in Continuous Cutting

Ideal for steady cutting operations with consistent feed rates and minimal vibration.

4.Cost-Effective Carbide Alternative

Provides carbide-level performance at a more competitive price point, improving overall tool cost efficiency.

5.Custom Sizes & Grades Available

Saw tip dimensions, grades, and TiC/TiCN ratios can be customized to meet specific blade designs and cutting requirements.

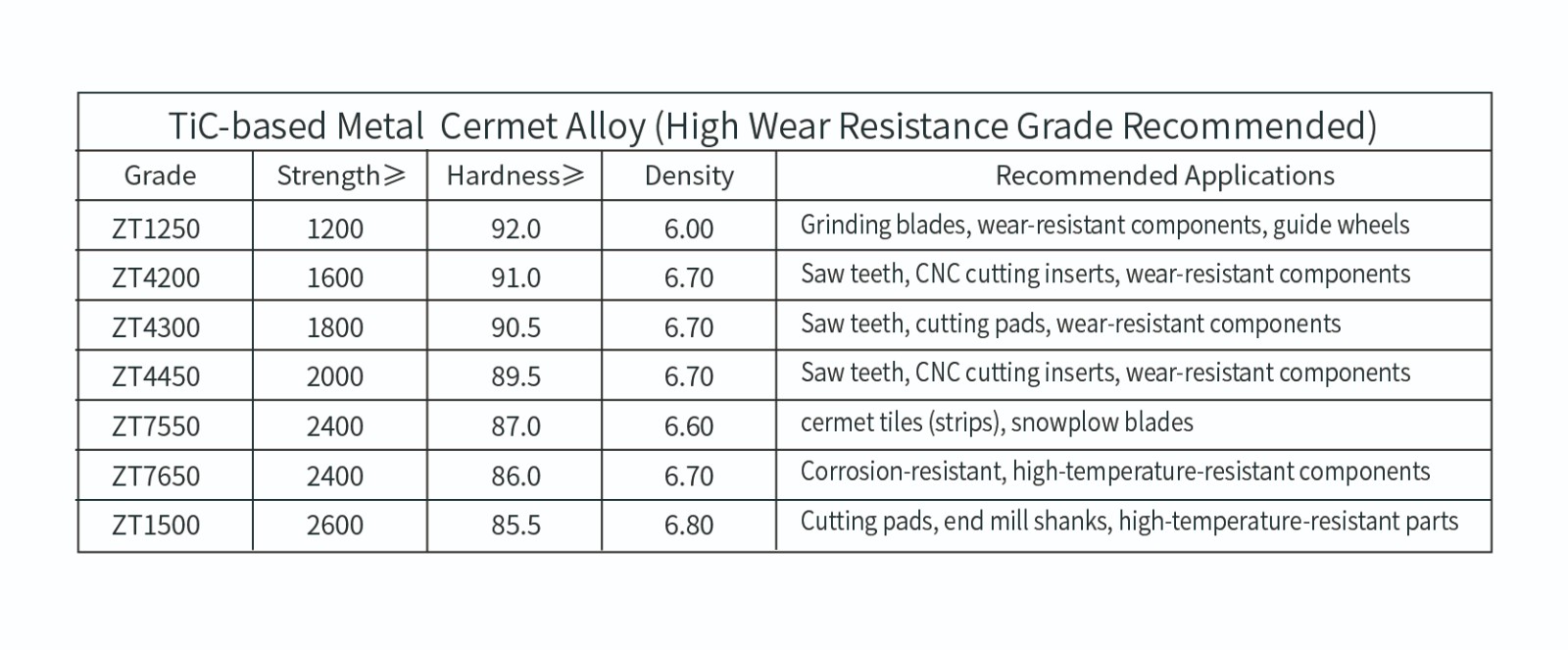

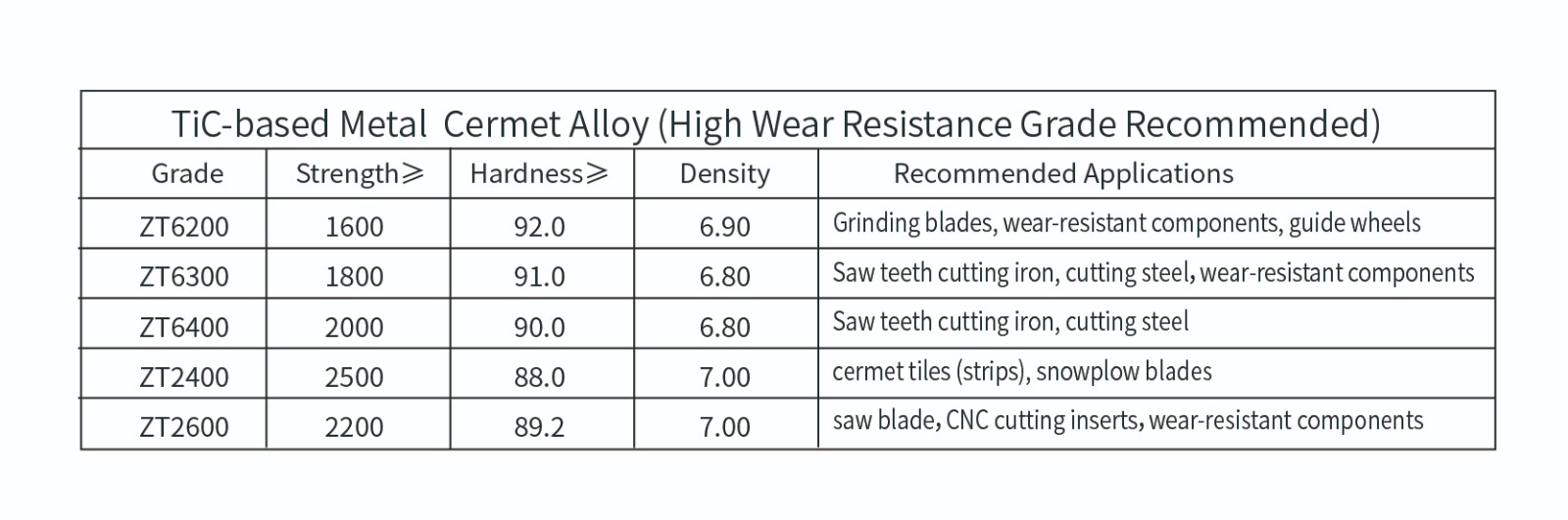

Parameter

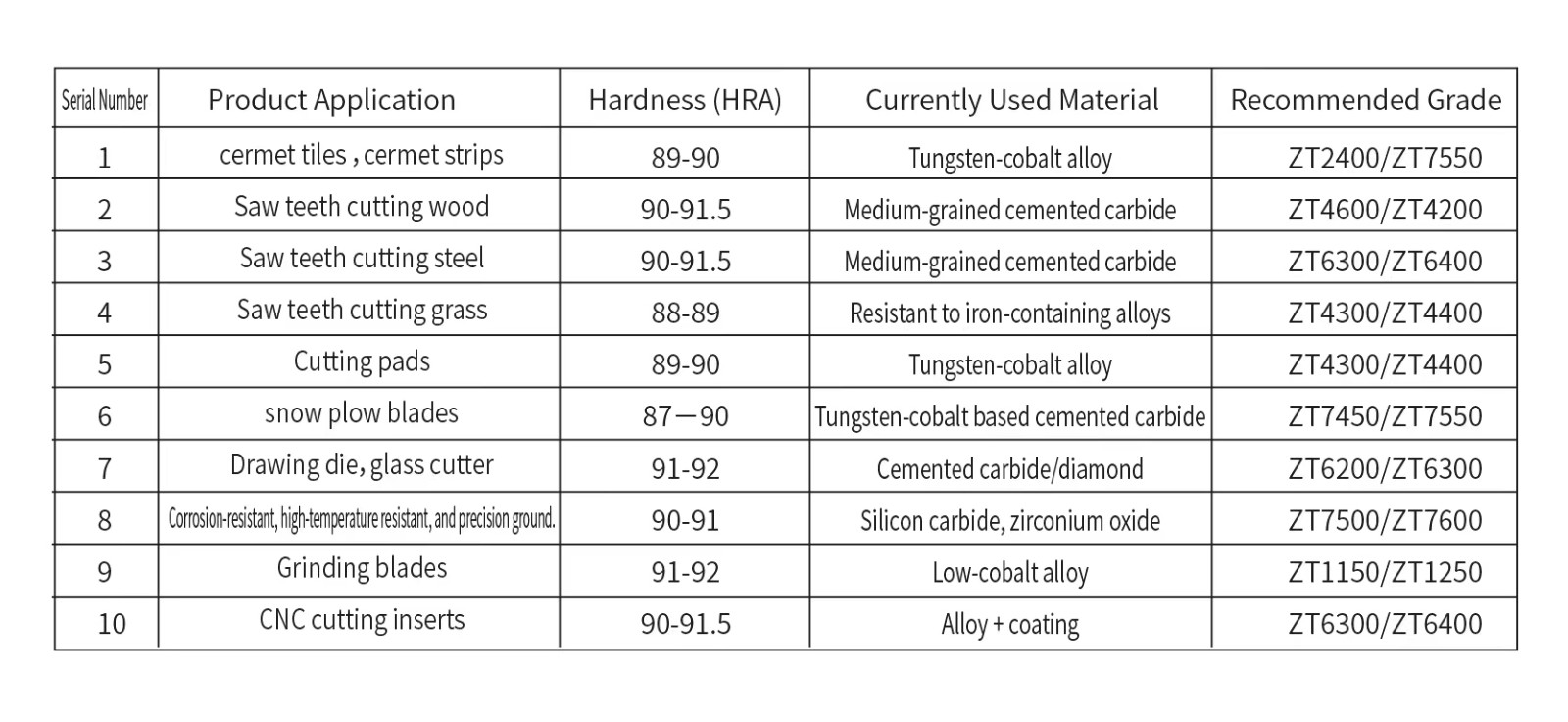

Application

Dimensional Accuracy & Consistency

Each saw tip is produced with precise dimensional control to ensure uniform size, flatness, and brazing compatibility. Consistent quality across batches supports stable tool assembly and predictable cutting performance.

Custom sizes and grades based on TiC / TiCN systems are available upon request to match specific sawing requirements.

For more information about metal ceramic saw tips (TiC/TiCN based), specifications, or pricing, please contact us at:

Email: sales1@jxcarbide.com

WhatsApp / WeChat: +86 18673306575

Suzy Chen