tungsten carbide rod high hardness cemented carbide solid round Cermet metal rods

Brand Name : JINXIN

Place of Origin : CHINA

Delivery Time : 7-14DAYS

Supply Ability : 1000000 PCS/MONTH

Matierial : Tungsten carbide、Cermet

1. The round bar is press molded by molding and extrusion. 2. The cemented carbide round bar is sintered by a low-pressure sintering integrated furnace, thus the overall performance is high. 3. The rough tungsten-cobalt carbide round bar, or the outer diameter of the round bar can be refined and polished according to any tolerance. The common tolerances are h6, h7, -0.005, etc., and the round bar end chamfer can also be processed. 4. Carbide round bar is suitable for the processing of general steel, cast iron, stainless steel, heat resistant steel, nickel base and titanium alloy. Recommended for general purpose carbide tool materials such as twist drills, end mills, taps, and gun drills.

Tungsten carbide rods description

Tungsten carbide rod is a high hardness and high strength product, which is composed of refractory metal compounds (hard phase) and bonding metals (bonding phase). Among them, refractory metal compounds such as tungsten carbide (WC) and bonding metals are often cobalt (Co). Alias: Due to different local names, tungsten carbide round rods are also called tungsten steel round rods or tungsten steel rods.

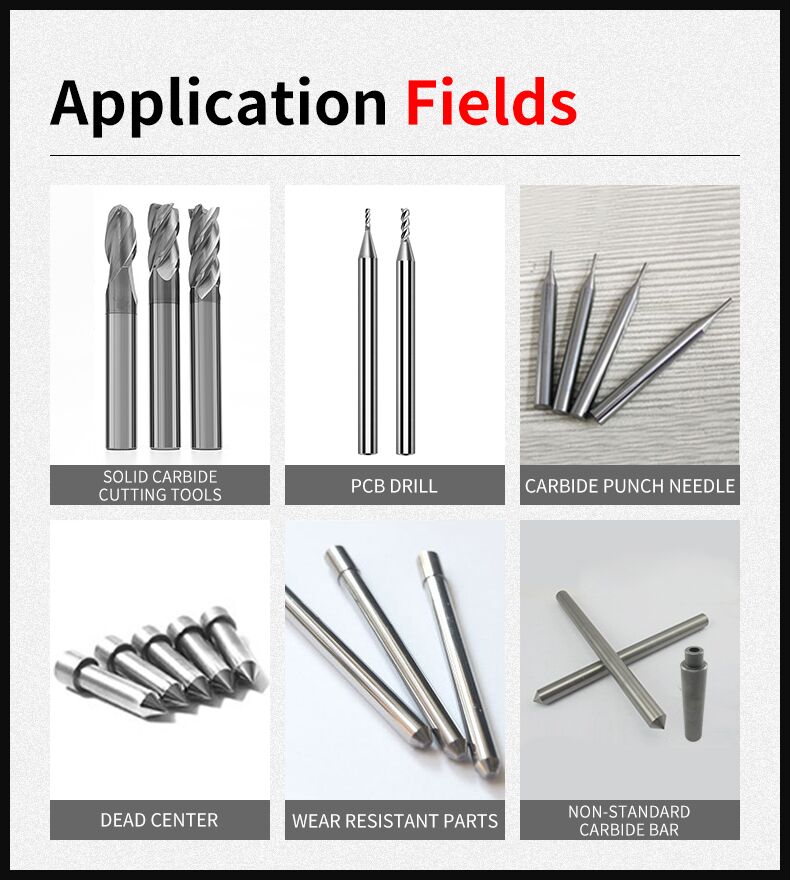

Tungsten Carbide Rods Application

Tungsten carbide rods are widely used in many fields due to their excellent performance:

Cutting tools: such as turning tools, milling cutters, planers, drills, boring tools, etc., used to cut various materials, including cast iron, non-ferrous metals, plastics, chemical fibers, graphite, glass, stone and ordinary steel, as well as difficult-to-process heat-resistant steel, stainless steel, high manganese steel, tool steel, etc.

Mold manufacturing: used to manufacture various molds to meet the production needs of different industries.

Other fields: It can also be used to make PCB micro drills, carbide engraving knives, carbide taps, carbide rotary files and other tools, as well as to process aluminum alloys, stainless steels, heat-resistant alloy steels and other product.

Tungsten carbide rods characteristics

1. Made by high quality tungsten carbide superfine powder

2. Precision equipment with 10MPa HIP-Sinter stove standardized manufacture.

3. High hardness and high strength

4. Special advantages: Red hardness, wear resistant, high elasticity modulus, TRS, chemical stability, impact resistant, low dilatation coefficient, heat conduction and electric conduction same with iron.

5. Special technology: high pressure sintering of high temperature vacuum. Reduce porosity, reduce compactness and mechanical property. Various grade, types and sizes.

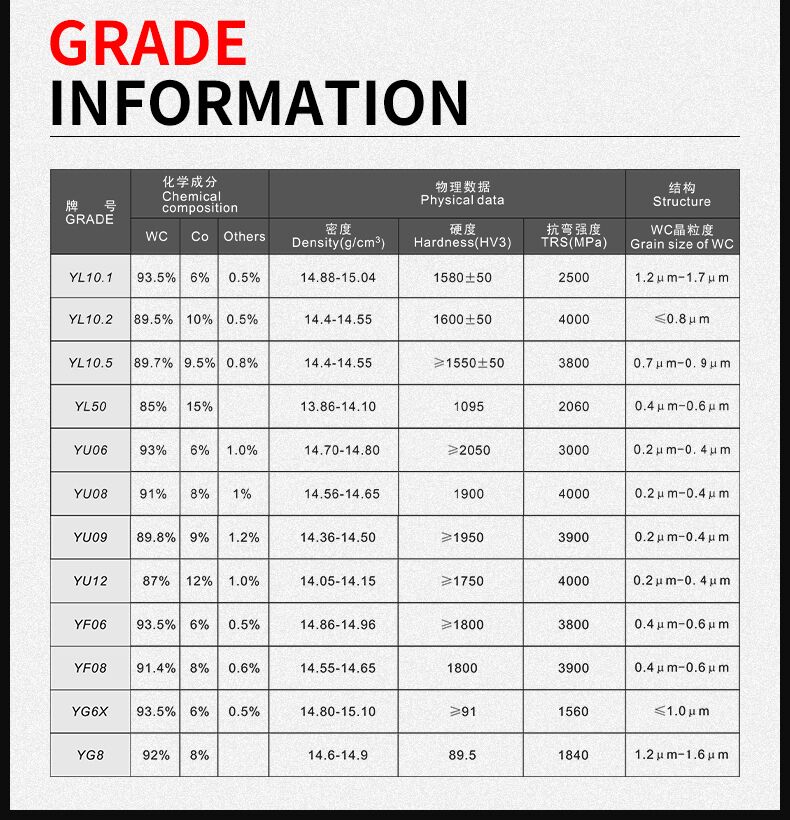

6. Different grade for your reference.

Contact:vincent

Mob: +8613357331966

wechat:13357331966

WhatsApp: +8613357331966

Email: jinxin012@ojinxin.com