Corrosion-Resistant Carbide Buttons for Marine Drilling Tools

Brand Name : JINXIN

Place of Origin : China

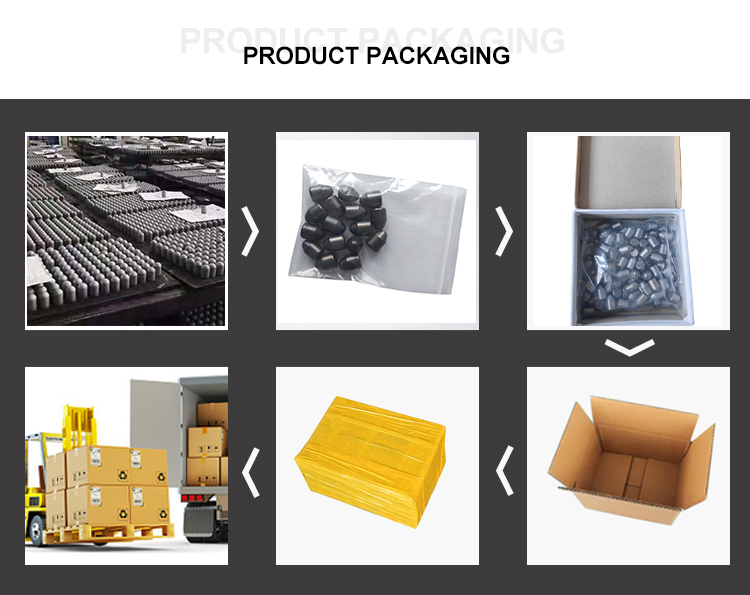

Packaging Details : Carton

Delivery Time : 7-15DAYS

Supply Ability : 1000000 PCS/MONTH

Matierial : Tungsten carbide,tungsten

High-performance tungsten carbide buttons for drilling and mining applications. As a custom tungsten carbide button manufacturer, we supply reliable tungsten carbide buttons for drilling and rock drilling tools. Buy tungsten carbide buttons in bulk for consistent quality and durability.

Product Description

These tungsten carbide buttons are engineered for multi-industry use, including foundation drilling, oil & gas, mining, and trenchless technology. They provide consistent bit performance even in hard, fractured, or abrasive rock. Advanced HIP sintering ensures maximum density and tool longevity. Whether you're using button bits for drilling rig systems or handheld devices, our carbide inserts maintain cutting precision and reduce wear. Choose from a variety of grades and geometries, or send us your specs for fully customized production.

Product Application

In stone quarries and aggregate production, carbide buttons are used in button bits to break down granite, limestone, and basalt. Their resistance to wear and chipping allows for faster cutting cycles and longer operational lifespan. Perfect for surface drilling, benching, and rock fragmentation in high-production environments.

Product Features

Each product undergoes precision grinding, HIP sintering, and rigorous testing for density, hardness, and dimensional accuracy, ensuring batch-to-batch consistency.

General Specifications

Material: Tungsten Carbide (WC)

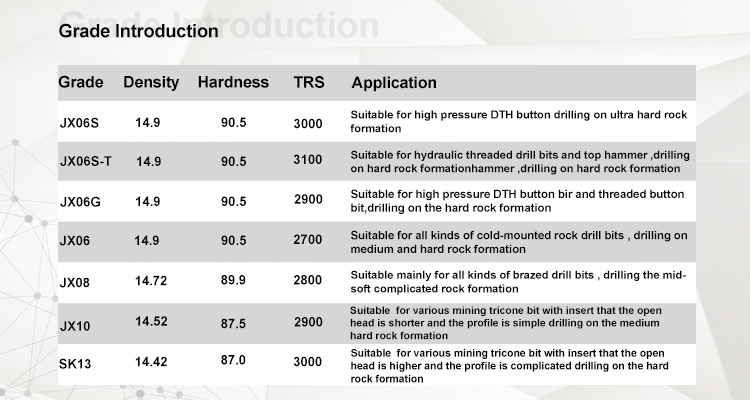

Density: 14.8-15.5 g/cm³

Hardness: ≥ 85 HRA

Grain Size: 0.3–0.7 µm

Cobalt Content: 6%–12%

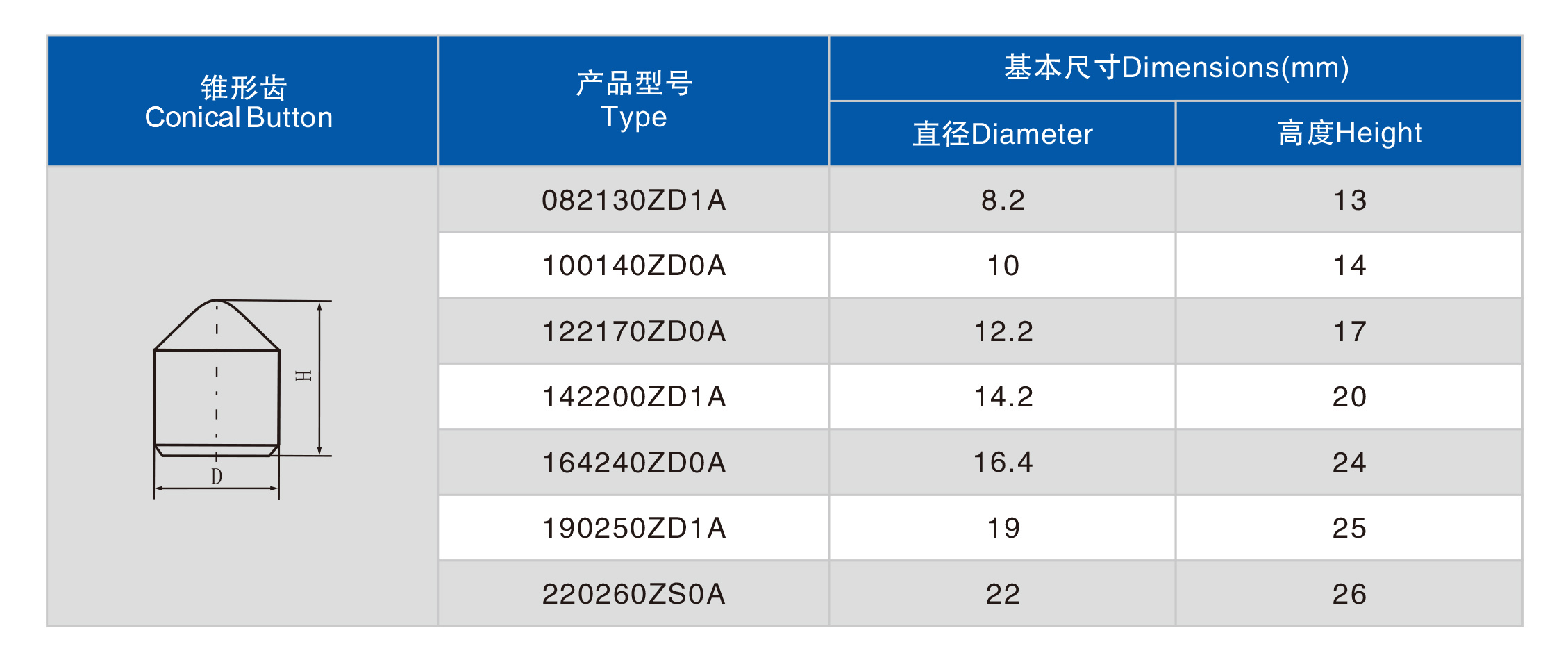

Available Shapes: Spherical, ballistic, conical, parabolic

Applications: DTH bits, top hammer bits, rotary drilling, mining, tunneling