Tungsten Carbide Rod with Central Coolant Hole in Standard Length Cermet metal rods

Brand Name : JINXIN

Place of Origin : CHINA

Delivery Time : 7-14DAYS

Supply Ability : 1000000 PCS/MONTH

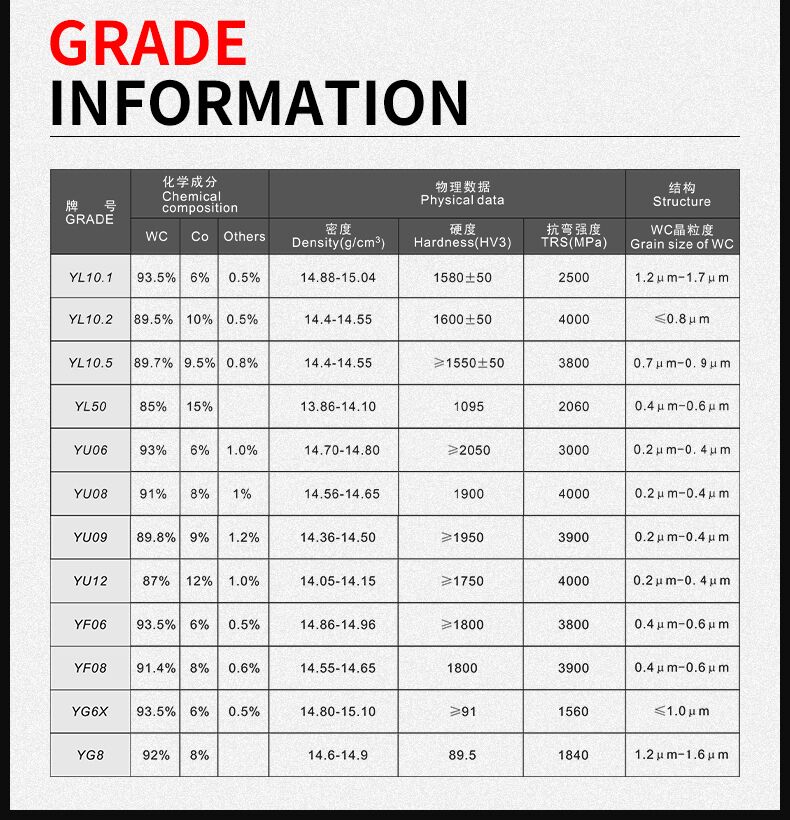

Matierial : Tungsten carbide、Cermet

1. 100% virgin raw material 2. High wear resistance 3. Senior engineer professional technical service team 4. 100% inspection before shipment 5. Shipped on time

Tungsten Carbide Rod with Central Coolant Hole description

Tungsten carbide rod with central cooling hole is a specially designed cemented carbide product, usually used in applications that require efficient heat dissipation and precise processing. This tungsten carbide rod has built-in cooling holes, which can introduce coolant during processing, effectively reducing cutting temperature, improving processing efficiency and tool life.

Tungsten Carbide Rod with Central Coolant Hole Features

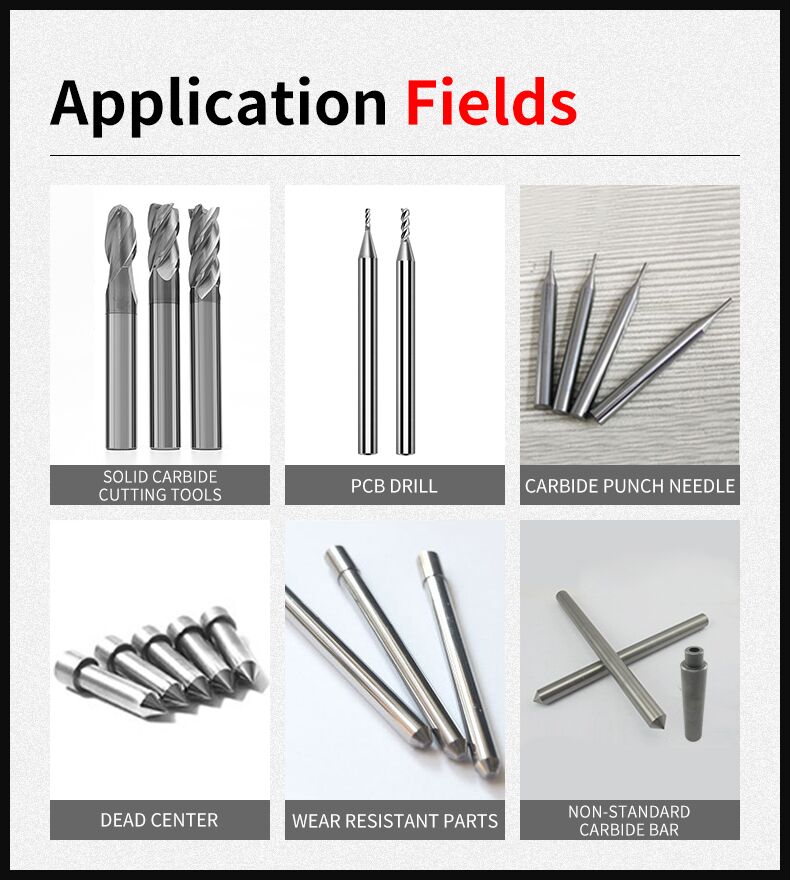

Material properties: Tungsten carbide has extremely high hardness and wear resistance, and is suitable for manufacturing tools such as tools and drills that require high strength and wear resistance.

Central cooling hole: The central cooling hole design allows coolant or coolant to flow through the inside of the rod to cool the heat accumulation of the tool during the cutting process, improving the life of the tool and processing efficiency.

Standard length: There are usually standard length specifications available to suit different processing needs and equipment.

Application areas: Commonly used in high-speed cutting, drilling, milling and other processes, especially in situations where high processing accuracy and workpiece surface quality are required.

The selection of this rod should be determined according to the specific processing requirements and use environment to ensure that the expected processing effect and tool life can be achieved.

Contact:vincent

Mob: +8613357331966

wechat:13357331966

WhatsApp: +8613357331966

Email: jinxin012@ojinxin.com