Tungsten round bar D6x330mm in YL10.2

Brand Name : JINXIN

Place of Origin : CHINA

Delivery Time : 7-14DAYS

Supply Ability : 1000000 PCS/MONTH

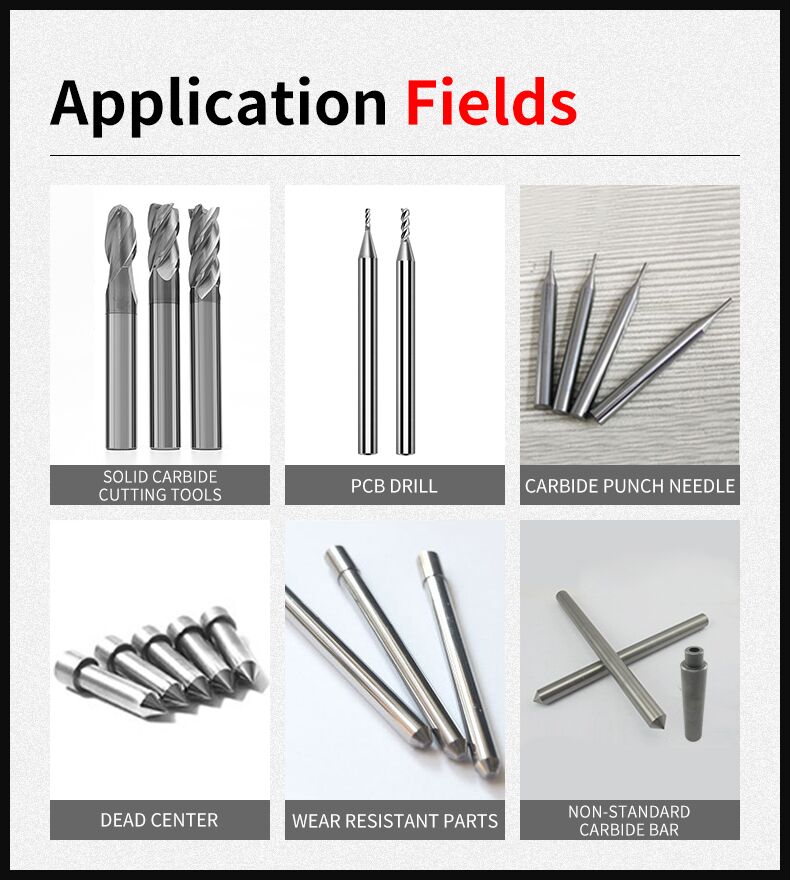

Carbide round bar is suitable for the processing of general steel, cast iron, stainless steel, heat resistant steel, nickel base and titanium alloy. The common tolerances are h6, h7, -0.005, etc., and the round bar end chamfer can also be processed.

Tungten carbide round bar features

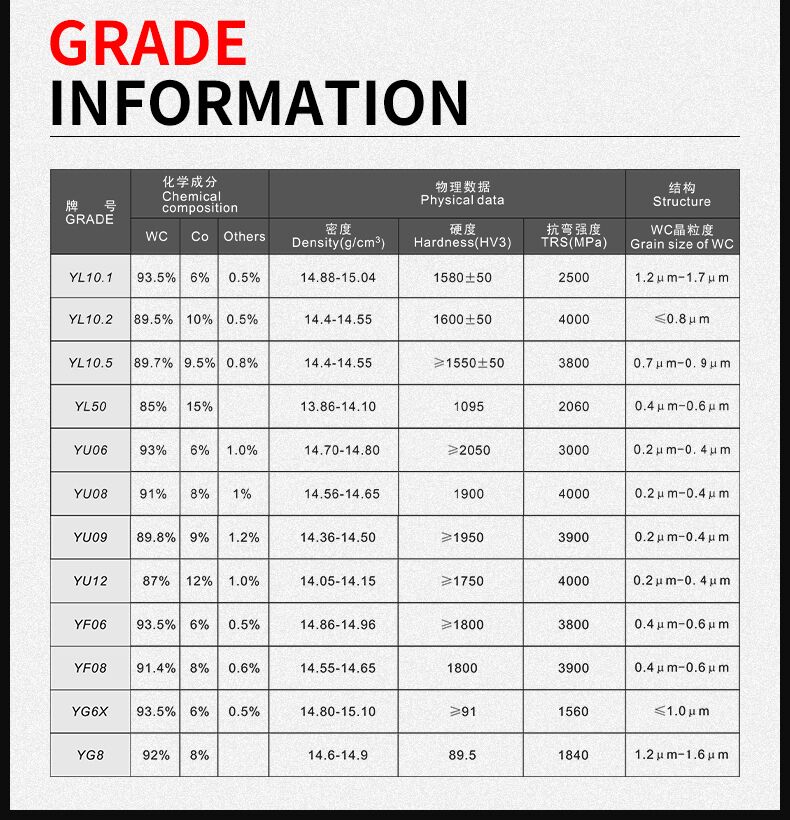

High Hardness and Wear Resistance: Its hardness is second only to diamond,

typically between HRA88 and HRA93, and it maintains excellent hardness and wear resistance even at high temperatures.

Excellent Mechanical Properties:

It exhibits stable mechanical properties,

including a high elastic modulus, high flexural strength, and a certain degree of impact toughness, making it easy to weld.

Heat and Corrosion Resistance:

It maintains stable performance even in high-temperature environments and exhibits excellent resistance to chemical corrosion,

including acids, alkalis, and high-temperature oxidation.

Production Process

The main process flow includes powder production, formulation according to application requirements, wet grinding, mixing, crushing, drying,

screening, addition of a molding agent, further drying and screening to obtain a mixture, granulation, pressing, molding, low-pressure sintering, molding (rough), cylindrical grinding (rough is generally not performed), dimensional inspection, and packaging and storage.

Core Advantages

1. Performance: "Hard Currency": High Hardness and Wear Resistance, Pushing the Limits of Processing

This is its core advantage, directly addressing the pain points of traditional high-speed steel and tool steel in machining high-hardness materials: easy wear and short life.

Its room-temperature hardness reaches HRA88-HRA93, second only to diamond, enabling stable cutting of difficult-to-machine materials such as stainless steel, titanium alloy, and high-strength cast iron.

Even in high-temperature cutting environments of 500-600°C, it maintains over 80% of its room-temperature hardness, preventing the loss of machining accuracy caused by high-temperature softening and significantly extending tool life (typically 5-10 times that of high-speed steel tools).

2. Operating Condition "Adaptability": Heat and corrosion resistance combined with mechanical stability enable it to adapt to complex applications.

Compared to ordinary metal materials, it maintains stable performance under harsh operating conditions, reducing equipment maintenance costs. On the one hand, it exhibits excellent resistance to acid and alkali corrosion and high-temperature oxidation, making it suitable for wear-resistant components (such as valve cores and nozzles) in the chemical industry, or for long-term operation in humid and corrosive environments. On the other hand, its high elastic modulus and flexural strength prevent deformation during high-speed rotation (such as milling and drilling), ensuring dimensional accuracy. This makes it particularly suitable for the "unmanned" continuous processing requirements of automated production lines.

3. Application Flexibility: Customization and Functional Expansion Cover Multi-Field Needs

It can meet both general standards and adapt to individual scenarios, breaking the "size limitations" and "functionality" of material applications. Standard specifications can be directly used to manufacture standard tools such as drills and end mills.

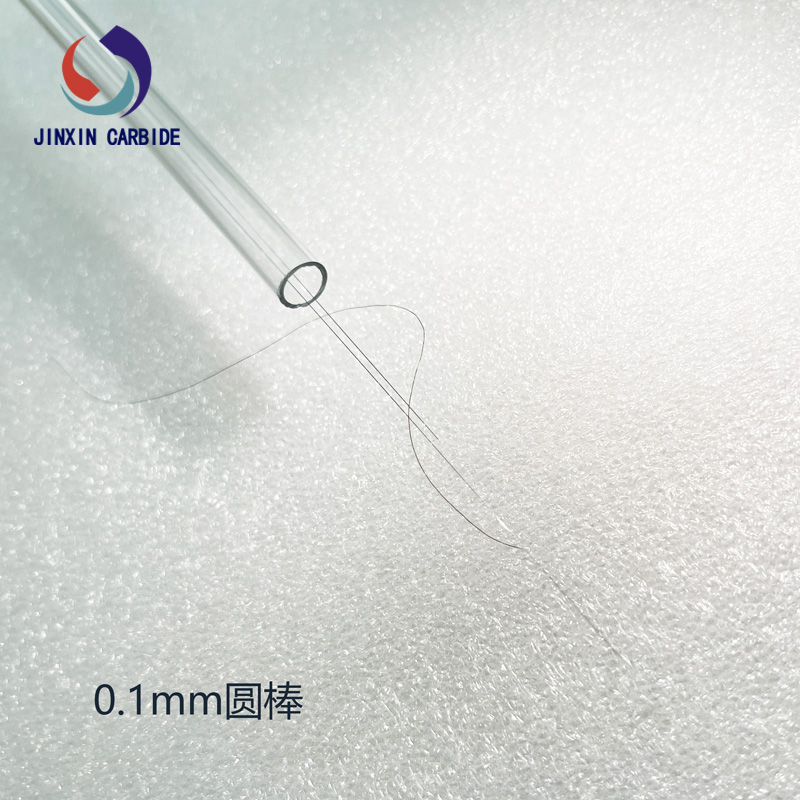

Customization allows for the production of micro round bars with a diameter of 0.1mm (suitable for precision drilling in the electronics industry) or long round bars with a length of 2000mm (for large roll components).

Some models with cooling holes also feature built-in cooling channels for rapid heat dissipation, further improving stability during high-speed processing and expanding its application potential in high-end fields such as aerospace and automotive manufacturing.

Diameter available: 0.1mm - 45mm

Length: 330mm (Max 1000mm)

Contact:vincent

Mob: +8613357331966

wechat:13357331966

WhatsApp: +8613357331966

Email: jinxin012@ojinxin.com