Ultra fine grain bearing ball for Petroleum industry bearing

Brand Name : JINXIN

Place of Origin : CHINA

Delivery Time : 7-15DAYS

Supply Ability : 10 ton/month

Matierial : Tungsten carbide,tungsten

1. 100% virgin raw materials. 2. Various kinds of grades are availalbe based on customer's application. 3. we have professional advanced production line and inspeciton equipments to ensure high quality products. 4. Precision Ground and high polishing process 5. High wear resistance,high hardness and impact toughness 6. Advanced technology , precise grinding.

Tungsten carbide balls are manufactured from a sintered material consisting of tungsten carbide and cobalt binder. They offer exceptional hardness, high wear resistance, and excellent corrosion resistance. Commonly used in high-precision bearings, valves, sealing components, gauges, and spray nozzles, these balls perform reliably even in the most demanding industrial environments, making them a superior alternative to steel or ceramic balls.

Solid carbide grinding ball

1. 100% raw materials

2. advanced equipments

3. Good abrasive resistance

4. High precision

| Tungsten carbide balls | |||||||||

| Type | Q-2.3 | Q-2.5 | Q-2.7 | Q-3.3 | Q-4.2 | Q-5.5 | Q-6 | Q-8 | Q-10 |

| Diameter | 2.3 | 2.5 | 2.7 | 3.3 | 4.2 | 5.5 | 6 | 8 | 10 |

| Tolerance (mm) | ±0.3 | ±0.3 | ±0.4 | ±0.4 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 |

| Type | Q-12 | Q-20 | Q-25 | Q-30 | Q-35 | Q-40 | Q-45 | Q-50 | Q-60 |

| Diameter | 12 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 |

| Tolerance (mm) | ±0.6 | ±0.6 | ±0.6 | ±1.0 | ±1.0 | ±1.2 | ±1.2 | ±1.6 | ±1.6 |

1. material : WC 94%, Co 6%

We can also provide other material as your request. Such as: WC 92%, Co 8%; WCNi

2. features :

high hardness , high precision , high antirust capability, high wear-resistant capability.

3. Application:

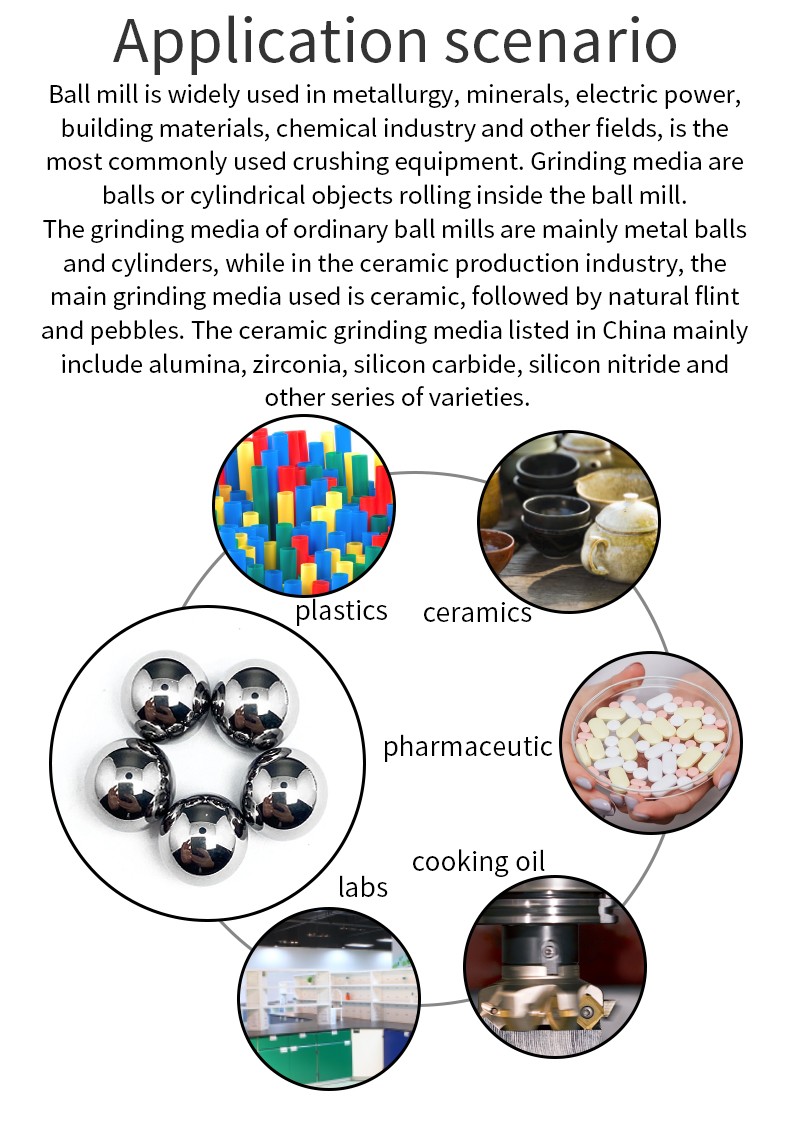

grinding, hardness examine machine, avigation , grinding machine, head pressure, and so on.