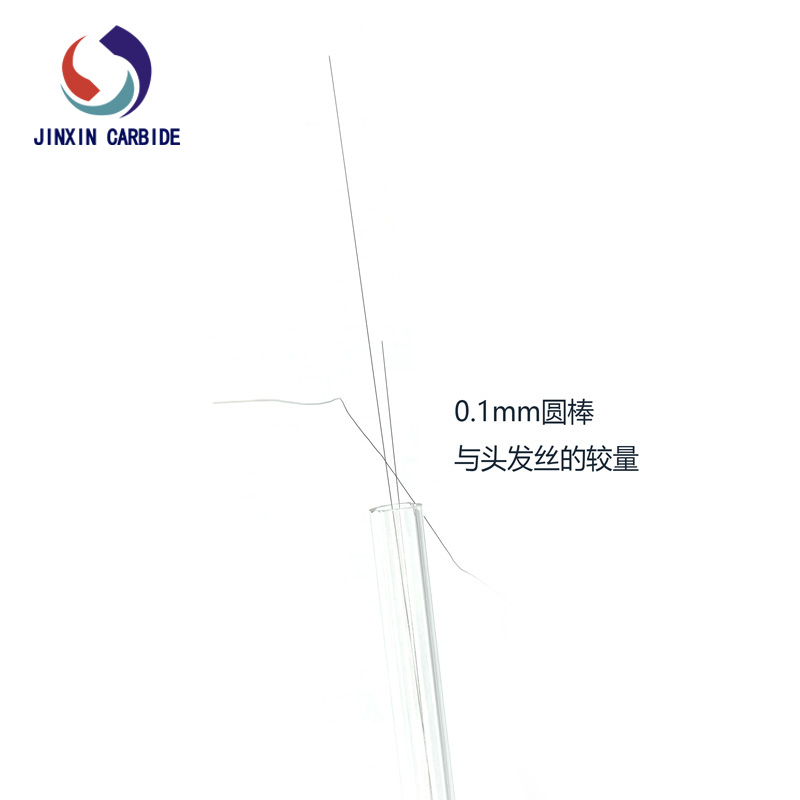

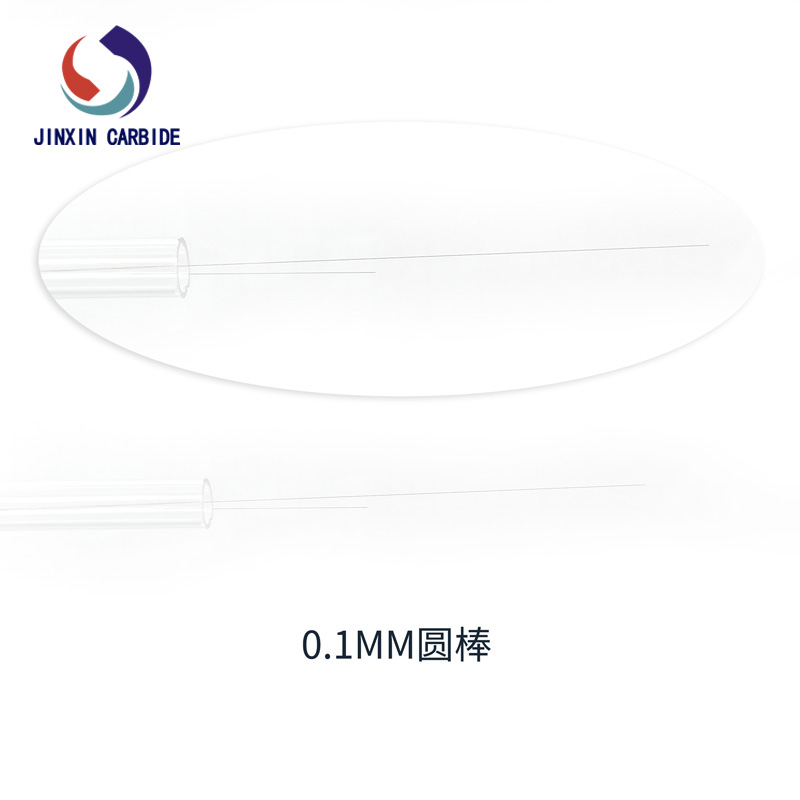

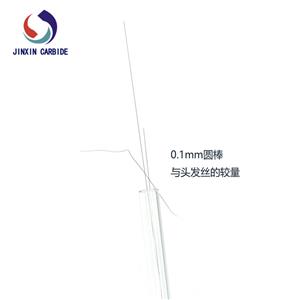

Ultrafine Tungsten Carbide Rods 0.1mm for Micro Drills & PCB Tools

Brand Name : JINXIN

Place of Origin : CHINA

MOQ : 100PCS

Packaging Details : Carton

Delivery Time : 5 DAYS

Supply Ability : 999999999PCS

Matierial : Tungsten carbide

Our ultrafine-grain tungsten carbide rods are specifically engineered for micro-cutting tool manufacturing, delivering consistent quality and exceptional dimensional accuracy even at extremely small diameters.

Product Application & Introduction

Product Overview

Core Performance Advantages

- Grain Size Optimization

Ultra-fine grain (0.4μm grades: JX25U, JX09U, JX06U): Provides superior hardness and wear resistance, ideal for finishing operations and high-wear applications.

Fine grain (0.7–1.0μm grades: JX20, JX06, JX40): Balances hardness with toughness, suitable for heavy cutting and impact-prone tasks.

- Cobalt Content Tailoring

High cobalt (12–15% grades: JX25U, JX40): Maximizes toughness and impact resistance, perfect for high-speed stamping dies and interrupted cutting.

Low cobalt (6–9% grades: JX06, JX09U, JX06U): Delivers maximum hardness and wear resistance, ideal for long-life cutting tools in abrasive materials.

- Precision & Stability

Tight diameter tolerance of ±0.002–±0.005mm ensures tool consistency.

Exceptional straightness (≤0.001mm/100mm) minimizes runout during high-speed machining.

High density (≥99.9%) guarantees uniform performance across the entire rod length.

Target Applications

| Application Area | Recommended Grades | Key Benefits |

|---|---|---|

| Semiconductor & Chip Manufacturing | JX25U, JX09U, JX06U | Ultra-fine grain ensures precision in micro-milling and drilling of wafers and packaging substrates, maintaining dimensional accuracy for 7nm+ advanced processes. |

| PCB & Substrate Processing | JX20, JX25U | High wear resistance enables tens of thousands of holes per drill, reducing tool change frequency and improving production efficiency. |

| Precision Mold Making | JX40, JX06U | High toughness and wear resistance extend the lifespan of mold cores, ejector pins, and stamping tools. |

| General Precision Machining | JX20, JX06 | Versatile performance across carbon steel, stainless steel, aluminum alloys, and plastics, suitable for general-purpose end mills and drills. |

Why Choose Our Tungsten Carbide Rods?

Industry-leading precision: Achieved through vacuum sintering, hot isostatic pressing (HIP), and ultra-precision grinding.

Customizable solutions: We offer tailored grain sizes, cobalt contents, and surface coatings (TiAlN, DLC) to meet your exact requirements.

Reliable quality control: Every batch undergoes rigorous testing for hardness, dimensional accuracy, and coating adhesion to ensure consistency.

Contact:vincent

Mob: +8615573301853

wechat:15573301853

WhatsApp: +8615573301853

Email: jinxin012@ojinxin.com