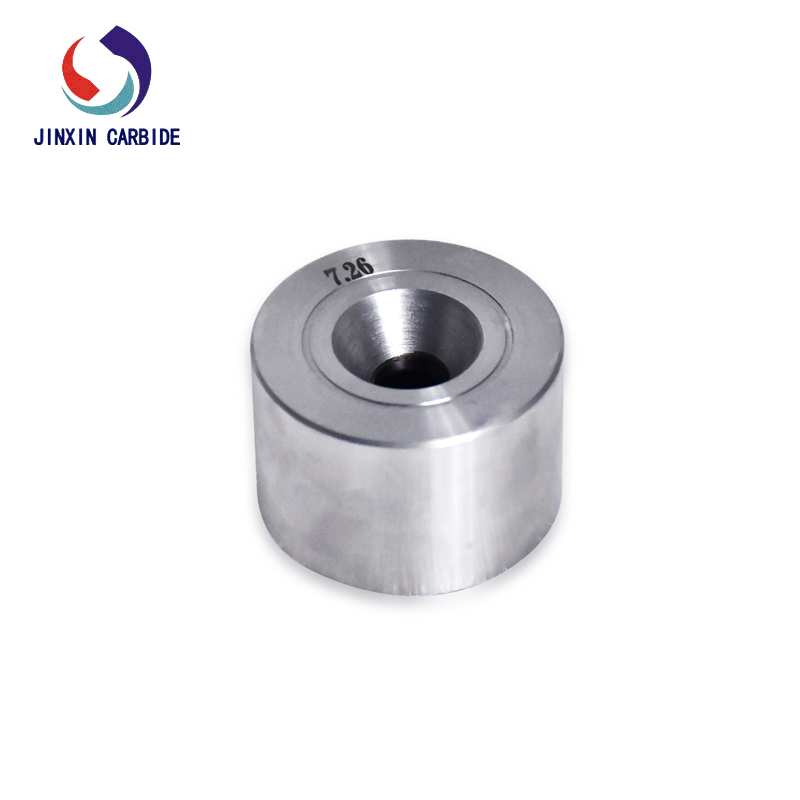

Cemented carbide wire drawing dies for copper wire

Tungsten Carbide Wire Drawing Dies (TCDD) is a die that uses high hardness, high wear-resistant tungsten carbide (WC) as the die material to draw metal wires to the desired diameter through the compression of the bore. Compared with other materials, tungsten carbide has a higher service life and greater wear resistance, and is particularly suitable for drawing non-ferrous metals such as copper, aluminum and brass.

During the copper wire drawing process, a lot of heat is generated by friction. The good thermal conductivity of Cemented Carbide can quickly dissipate this heat, effectively reducing dimensional changes in the mold due to thermal expansion, thus maintaining processing accuracy. This is critical for the production of high-precision copper wires, such as the ultra-fine copper wires used in precision electronic devices.

Copper wire has good ductility, but mold wear still occurs during high-speed drawing. Cemented Carbide dies can effectively reduce the wear rate and ensure the surface finish and dimensional accuracy of copper wires, and are suitable for multi-stage drawing or high-speed drawing equipment. Compared with ordinary molds, the service life of cemented carbide wire drawing dies can be extended several times or even dozens of times. For the diameter tolerance, roundness and other precision indicators of copper wire, carbide wire drawing dies can achieve more stringent control. Whether it is processing soft pure copper wires or higher hardness copper alloy wires, Cemented Carbide Wire Drawing Die is capable of doing the job.