Tungsten Carbide Roller vs. Steel Roller

In the modern rolling industry, rolls are key components that directly affect rolling efficiency, product quality, and production costs. Carbide rolls and steel rolls differ significantly in material properties, performance, and application scope.

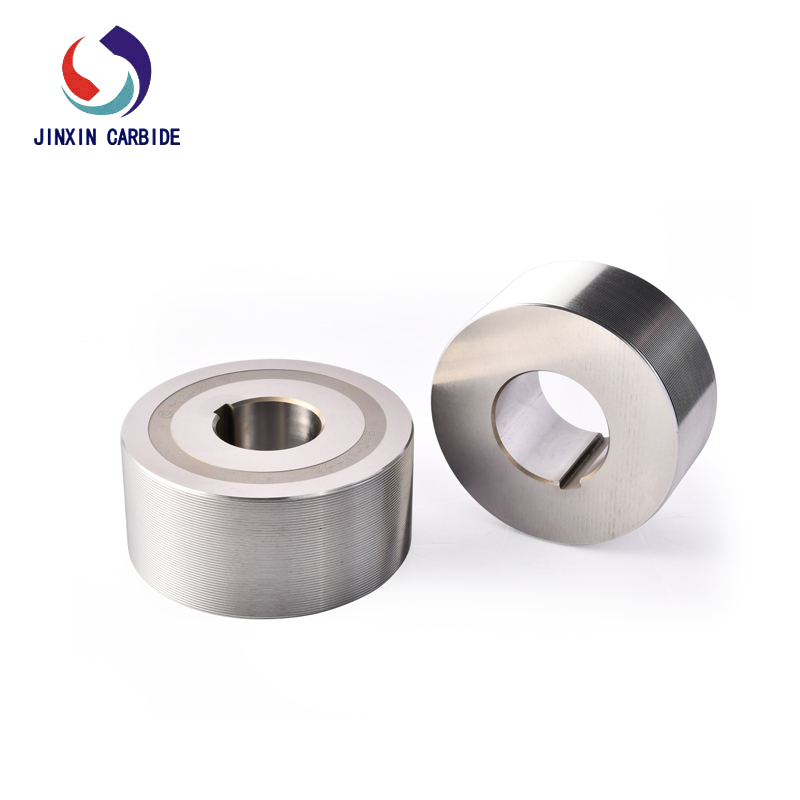

Tungsten Carbide rolls are primarily manufactured through powder metallurgy, using hard phases like tungsten carbide and binding agents such as cobalt. They offer extremely high hardness (HRA 89–93) and excellent wear resistance. These rolls are resistant to cracking and dimensional deformation even under high-speed and high-temperature conditions, significantly reducing the need for replacement and maintenance. In addition, carbide rollers offer high machining precision and can greatly enhance the dimensional consistency and surface finish of the final product.

However, WC rollers have certain limitations, including low toughness and a higher risk of cracking under heavy loads or abnormal impact conditions. Therefore, in primary or rough rolling applications involving frequent high-impact loads, carbide rolls should be used with caution.

Steel rolls, in contrast, are typically made from cast iron or cast steel and are manufactured through casting or forging processes. Although their hardness and wear resistance are inferior to cemented carbide rolls, they offer superior toughness and impact resistance. They are suitable for primary rolling mills, medium and heavy plate rolling mills, and other applications involving heavy loads and strong impact forces, with the added advantage of lower initial cost.

However, steel rolls tend to soften at high temperatures, lack sufficient wear resistance, and require frequent replacement and regrinding, potentially increasing long-term operational costs.

In summary, for enterprises seeking high-precision, high-efficiency, and long-lifespan continuous rolling processes, cemented carbide rolls are undoubtedly the superior choice. However, for primary rolling operations or where investment budgets are limited, steel rolls continue to offer significant practical value.