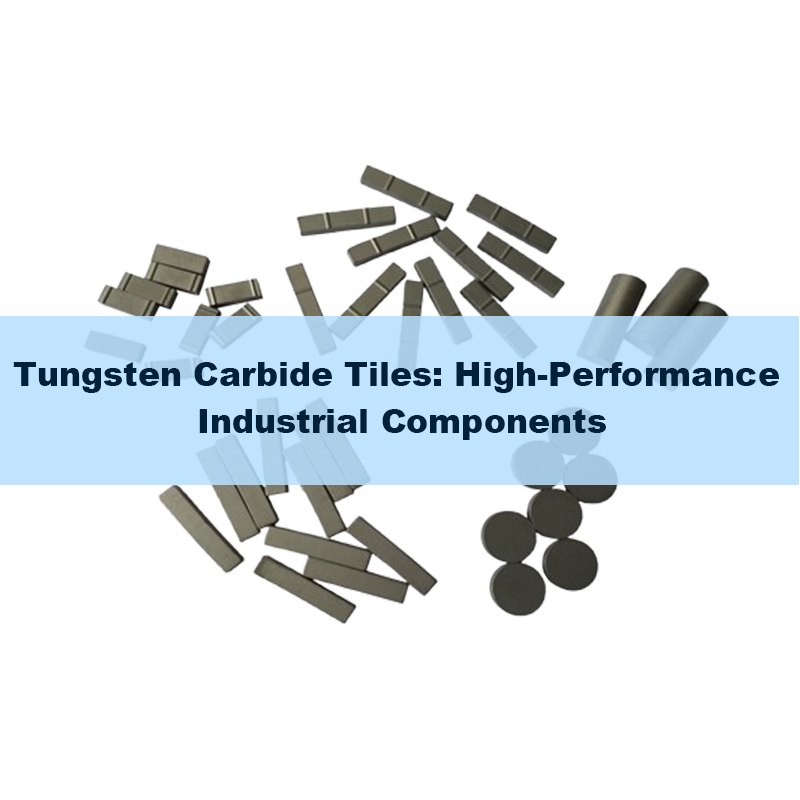

Tungsten Carbide Tiles: High-Performance Industrial Components

Tungsten carbide tiles are industrial components made from tungsten carbide (WC) and are known for their high hardness, excellent wear resistance, and good corrosion resistance.

They are typically manufactured using a powder metallurgy process, in which tungsten carbide powder is mixed with a binder such as cobalt, then pressed and sintered. Tungsten carbide tiles are available in a variety of shapes and sizes, including rectangular, round, and trapezoidal designs. Jinxin can also customize them to meet specific application requirements.

These tiles are widely used in industries such as oil and gas drilling, mining, construction, and agriculture. For example, in oil and gas drilling, they are used to make radial bearing tiles that withstand extreme temperatures, pressures, and corrosive fluids. In agricultural machinery, they serve as wear-resistant components like plowshares and tiller blades, significantly extending component life and reducing maintenance costs.

Using tungsten carbide tiles as wear-resistant components offers many advantages. Their exceptional wear resistance allows them to endure high levels of abrasion, making them ideal for demanding environments such as mining and construction, and reducing the need for frequent part replacement. Additionally, the durability of tungsten carbide tiles helps improve overall equipment efficiency and productivity, as they continue to perform reliably even under harsh conditions. Selecting the right tungsten carbide tiles can further enhance work efficiency.