Tungsten carbide wire drawing dies sizes

When choosing the right size wire drawing die, you should consider the following four factors: wire material: pure copper, copper alloy, aluminum, brass, etc.; target diameter: finished wire thickness to choose the diameter of the die hole; drawing speed: high-speed drawing needs to choose a higher heat-resistant and abrasion-resistant design; equipment type: matching the equipment required for the outer diameter and height.

Die hole is one of the core parameters of wire drawing dies, which directly determines the diameter of wire that can be drawn. The range of hole diameters for different applications are as follows:

Recommended hole diameter for ultra-fine copper wire and electronic wire: 0.02 mm - 0.10 mm

Recommended hole diameter for ordinary wire and cable: 0.1 mm - 3.0 mm

Recommended hole diameter for industrial coarse copper wire and aluminum wire: 3.0 mm - 20 mm

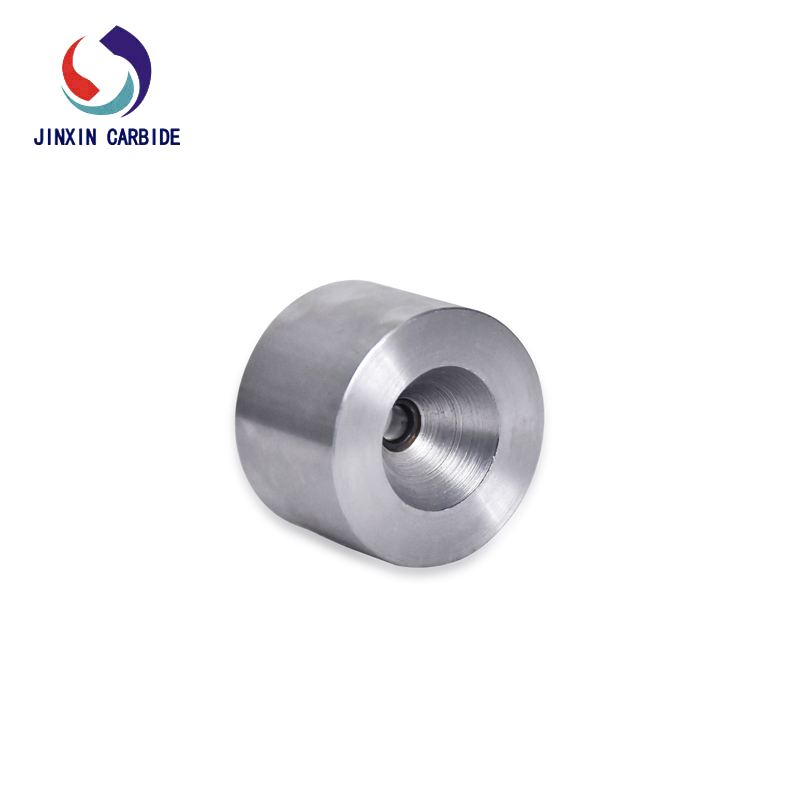

Tungsten carbide dies usually have standardized dimensions in order to adapt to different wire drawing equipment. The following are common models:

Die models: D3, D12, D25, corresponding to the outer diameter (OD) of 25 mm, 36 mm, 50 mm, height (H) of 10 mm, 25 mm, 30 mm. According to customer demand, we can also customize non-standard size molds for automated high-speed wire drawing equipment. If you are looking for tungsten carbide wire drawing dies, you can contact us for design and production.