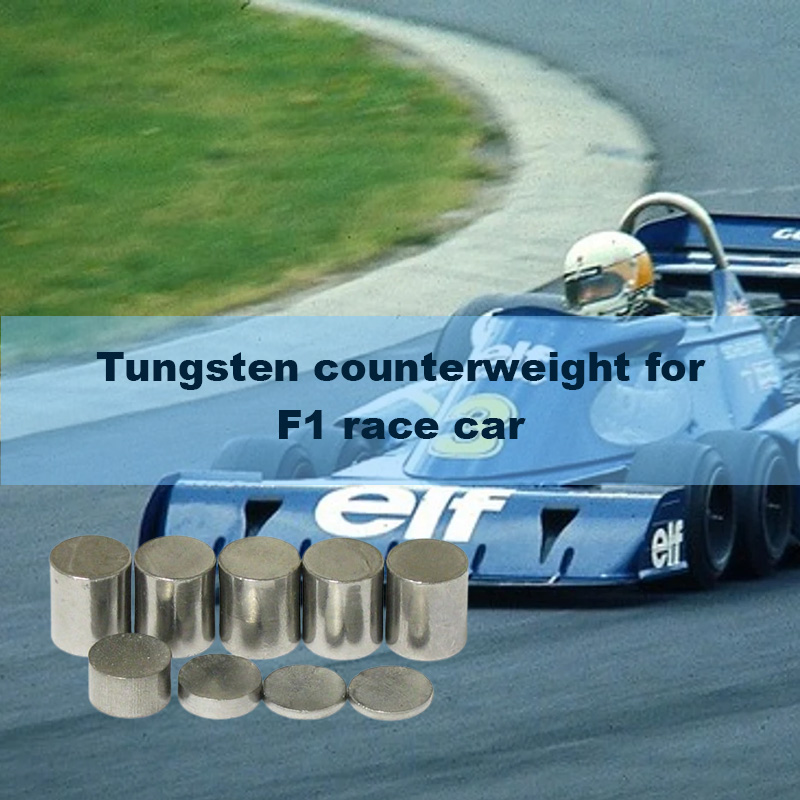

Tungsten counterweight for F1 race car

In the high-speed world of Formula 1 racing, even the slightest change in weight can significantly impact a car's handling, stability, and overall performance. To optimize the vehicle's center of gravity and enhance cornering control and high-speed stability, tungsten counterweights have become an essential tool in the arsenal of F1 engineers.

Tungsten alloy is a high-density material, with a typical density ranging from 17.0 to 18.5 g/cm³, making it an ideal choice for weight balancing in F1 cars. This exceptional density allows tungsten counterweights to deliver the required mass in a compact form. As a result, engineers can precisely adjust the car's balance without compromising its aerodynamic profile. In F1 car design, tungsten counterweights are typically installed on the underside of the chassis, around the gearbox, or near the suspension system—areas where weight distribution directly influences grip and steering responsiveness during cornering.

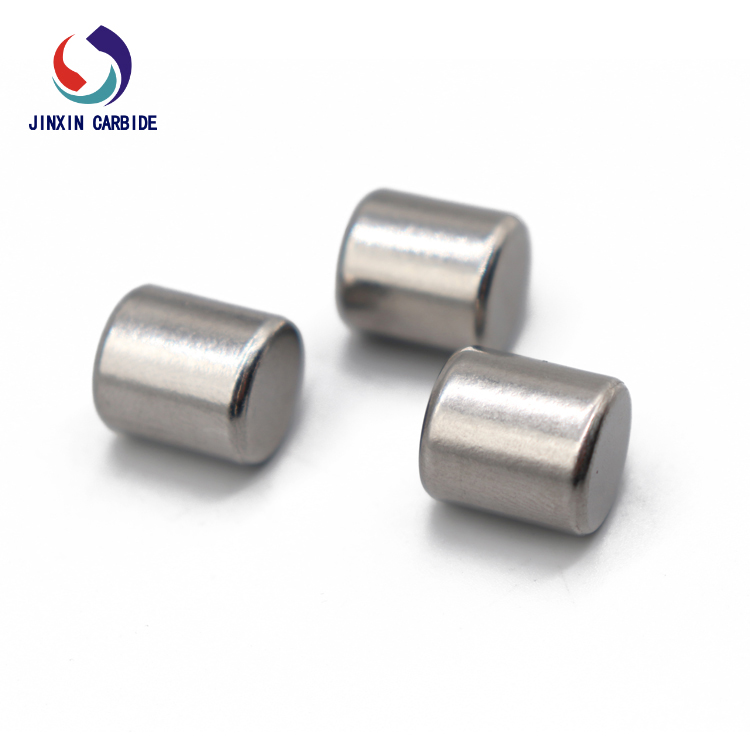

With a tensile strength ranging from 700 to 1100 MPa, tungsten alloy can withstand the extreme demands of racing conditions. It is also highly machinable and can be customized into various geometric shapes to meet specific balancing requirements. During a race, factors such as fuel consumption and tire wear continuously alter the car's weight distribution. Teams can respond by quickly adjusting or replacing tungsten counterweights to restore the vehicle's optimal balance, ensuring consistent handling and peak performance throughout the race.

From enhancing vehicle stability and control to helping teams win championships, the value of tungsten counterweightscannot be underestimated. That's why it's crucial to choose the right tungsten counterweight manufacturer. Jinxin specializes in the production of high-quality tungsten counterweights and offers customized solutions tailored to the demands of motorsport applications. Contact us anytime for expert consultation and support.