What are the advantages of tungsten carbide plunger?

Plungers are vital components in a wide range of pumps and mechanical equipment, commonly used for high-pressure transmission, sealing, and wear-resistant applications. As a key element for transferring pressure and sealing media, the performance of the plunger directly impacts the efficiency, service life, and safety of the entire system.

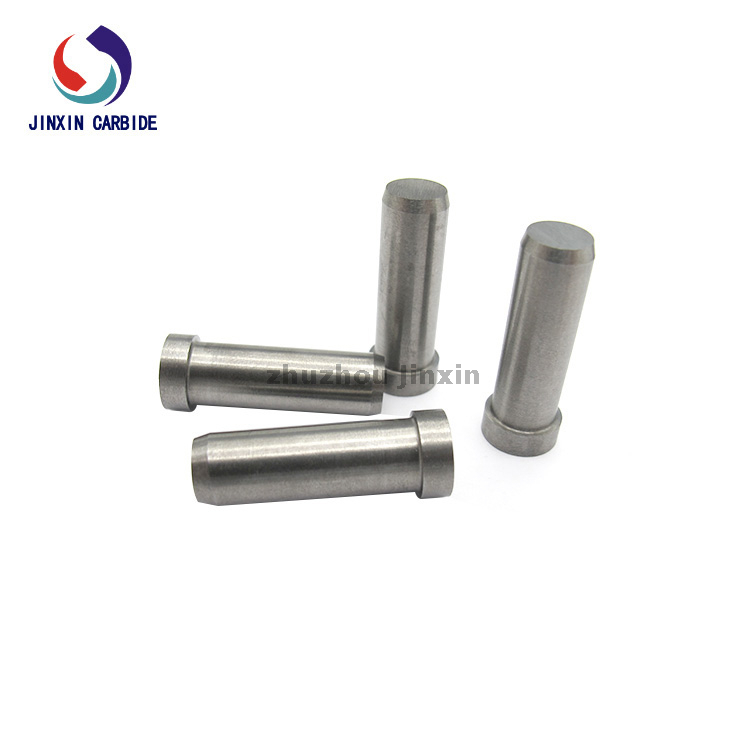

In recent years, the high wear resistance tungsten carbide plunger has become the preferred choice across many industries. Thanks to its exceptional hardness, wear resistance, and corrosion resistance, it delivers outstanding performance in demanding applications such as petroleum, chemical processing, metallurgy, and high-pressure cleaning equipment.

Key Advantages of Tungsten Carbide Plungers:

Superior Hardness and Wear Resistance

With a hardness second only to diamond, tungsten carbide far outperforms stainless steel and alloy steel. These plungers withstand heavy friction and extreme pressure, significantly extending service life and minimizing downtime caused by part replacement.

Outstanding Corrosion Resistance

The inherent chemical stability of tungsten carbide ensures reliable operation in harsh environments, including chemical plants, marine applications, and the oil and gas industry, reducing the risk of plunger failure due to corrosion.

High Strength and Toughness

Beyond hardness, tungsten carbide plungers offer excellent bending strength and toughness. They resist cracking and breaking under extreme pressure or impact, making them particularly suitable for high-load applications such as mining and oil drilling.

Low Friction and Enhanced Efficiency

A mirror-polished surface gives the plunger a remarkably smooth finish, reducing friction, lowering energy consumption, and minimizing seal wear. This improves pump efficiency and extends the lifespan of the entire system.

Although the initial investment in tungsten carbide plungers may be higher, their long service life, reduced maintenance needs, and superior reliability deliver excellent long-term value. By lowering replacement costs and minimizing downtime, they greatly improve overall equipment efficiency and economic performance.

Choosing a high wear resistance tungsten carbide plunger ensures stable and reliable operation, even under the most demanding working conditions. For more information, contact Jinxin—our team is always ready to provide professional support and high-quality solutions tailored to your needs.