What is the difference between cermet rod and carbide rod?

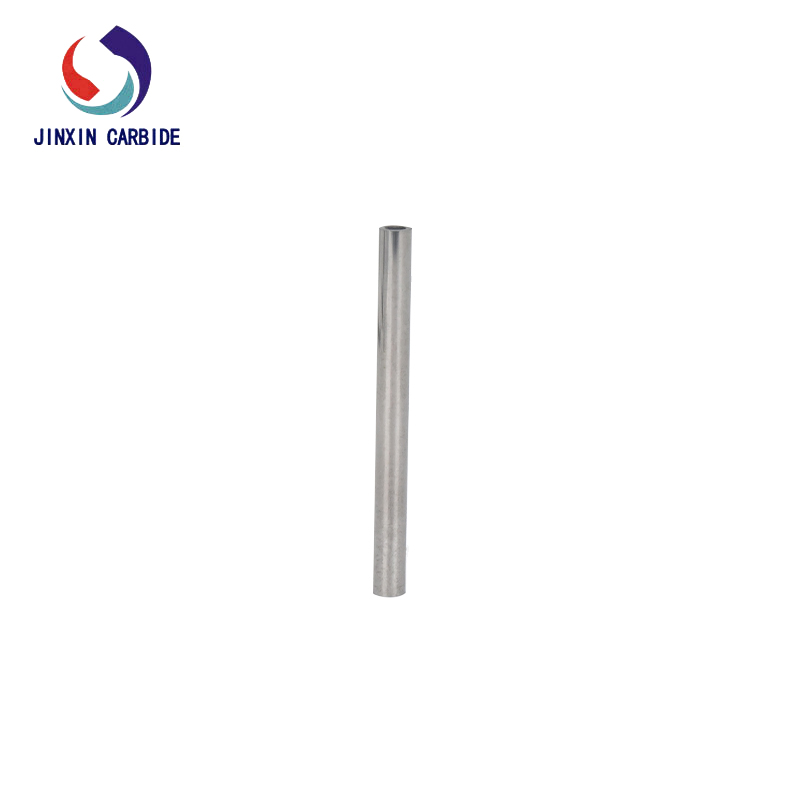

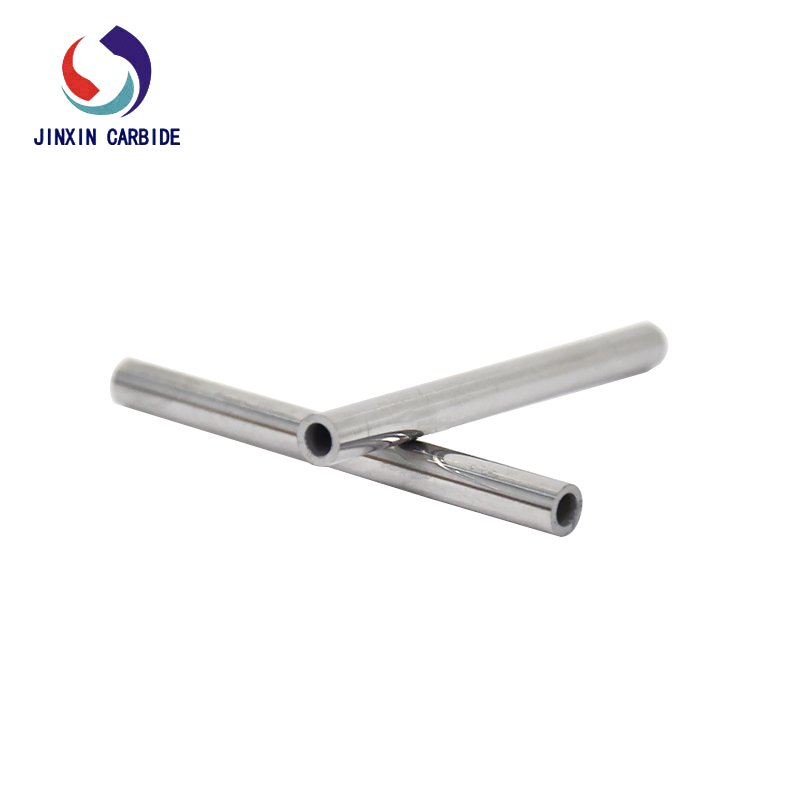

In industrial machining, cermet rods and tungsten carbide rods are two common and important tool materials. They are similar in appearance and have a color close to metallic gray.

Cermet rods are also a hard material produced using powder metallurgy, but tungsten carbide rods primarily consist of tungsten carbide (WC) particles with cobalt (Co) as a binder. Cermet rods typically consist of ceramic phases such as titanium carbide (TiC) or titanium nitride (TiN) bonded to metals such as nickel (Ni) or cobalt (Co).

Tungsten carbide rods, by comparison, offer greater impact and fracture resistance, allowing them to withstand high cutting forces and intermittent cutting. They are well-suited for machining high-strength materials such as steel, stainless steel, and cast iron. Cermet rods are known for their higher hardness and chemical inertness, making them suitable for semi-finishing and finishing operations, achieving an exceptionally smooth surface finish. However, they are relatively brittle and unsuitable for heavy cutting environments.

Carbide round rods are widely used in the manufacture of tools such as end mills, drills, taps, turning tools, and reamers. Suitable for cutting a wide range of materials, including carbon steel, stainless steel, titanium alloy, and cast iron, they are one of the most versatile tool materials. Cermet round rods are particularly suitable for high-gloss finishing, mirror cutting, mold polishing, and wear-resistant parts. Under high speeds and low cutting loads, cermets offer excellent surface quality and dimensional accuracy.

Jinxin Company has long specialized in the research and development and manufacturing of high-performance rods, including carbide round rods, cermet rods, and various composite materials. We can customize solutions based on customer drawings, flexibly adjusting grades, dimensions, tolerances, and performance specifications. For more product information or customized services, please feel free to contact us.