why choose wear-resistant roller rings for pre-finishing stands?

The pre-finishing stand is a critical pre-rolling equipment in hot or cold rolling production lines. Its core task is to initially roll, shape, and reduce hot steel billets (typically at 1000-1250°C), providing them with uniformly sized, surface-quality semi-finished billets for the subsequent finishing process. In the pre-rolling stand, the rollers must withstand extreme conditions such as high temperatures, high pressures, heavy loads, and continuous friction. Consequently, an increasing number of steel mills are opting for higher-performance, wear-resistant rollers to withstand these demanding production environments.

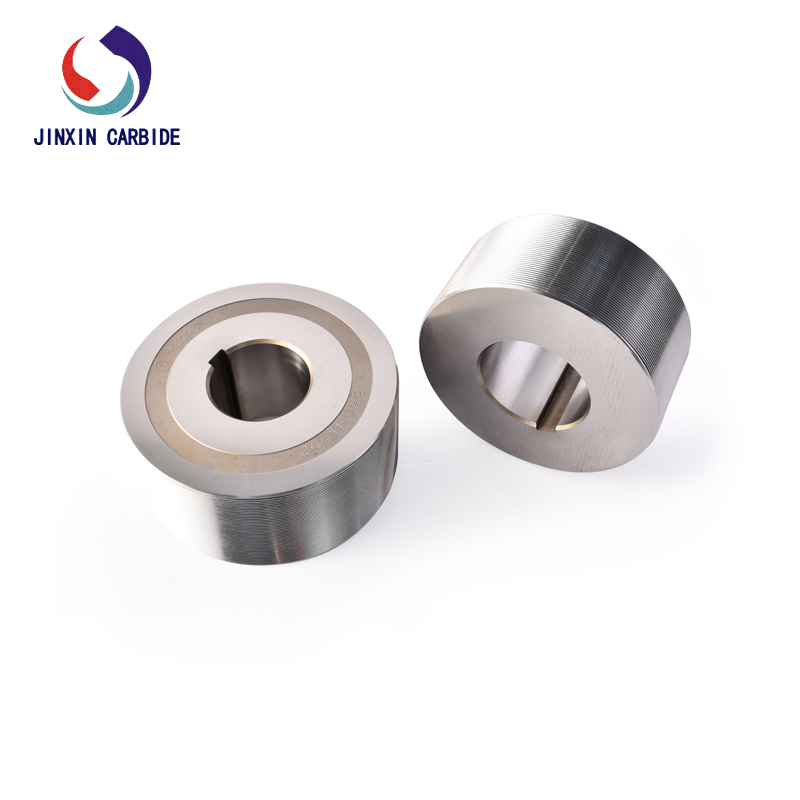

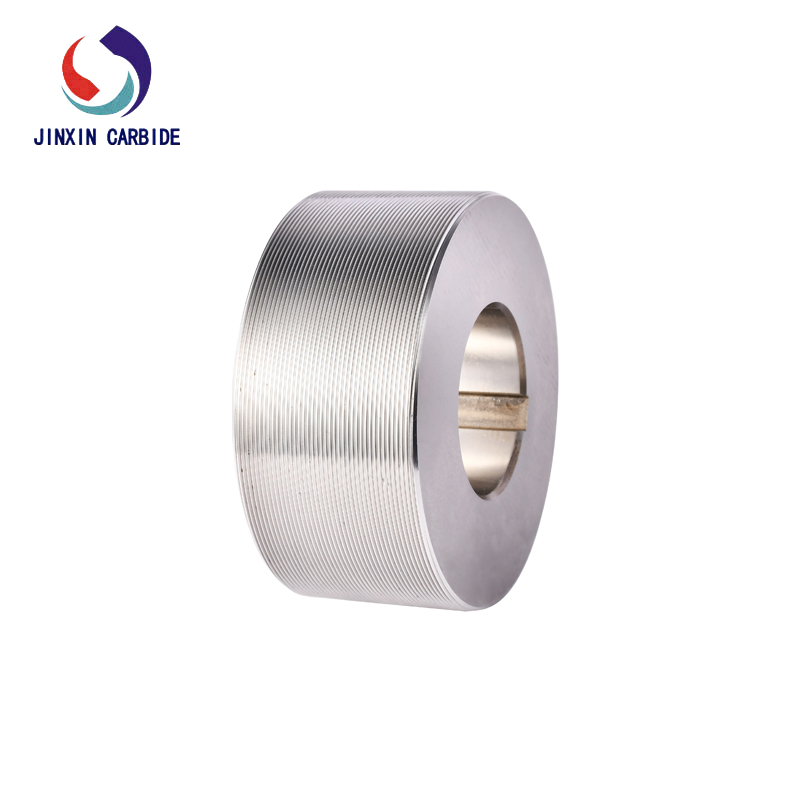

Wear-resistant rollers are typically manufactured from high-performance materials such as tungsten carbide, cermet, or high-speed steel (HSS), with tungsten carbide-based tungsten carbide rollers being the most common.

Tungsten carbide roll rings offer excellent hot hardness and thermal crack resistance, ensuring long-term use without cracking or deformation. Their low-friction, high-gloss surface effectively reduces metal adhesion and surface scratching, ensuring smooth, consistent finished steel. Furthermore, tungsten carbide roll rings possess excellent compressive strength and chemical stability and can be customized to suit different rolling mills and operating conditions, making them an ideal choice for improving pre-rolling mill efficiency, extending equipment life, and enhancing product quality.

Selecting the right wear-resistant roll rings is the first step to maintaining the continuous efficiency of your rolling mill. If you require a customized roll ring solution for different rolling conditions, please contact us for professional technical support and material optimization recommendations.

Using wear-resistant roll rings in pre-rolling mills can significantly improve equipment efficiency and product quality. The extended lifespan of wear-resistant roll rings effectively reduces replacement frequency and downtime for maintenance. While the initial investment may be slightly higher, the longer service life and reduced replacement times result in lower overall costs, making them a worthwhile investment.