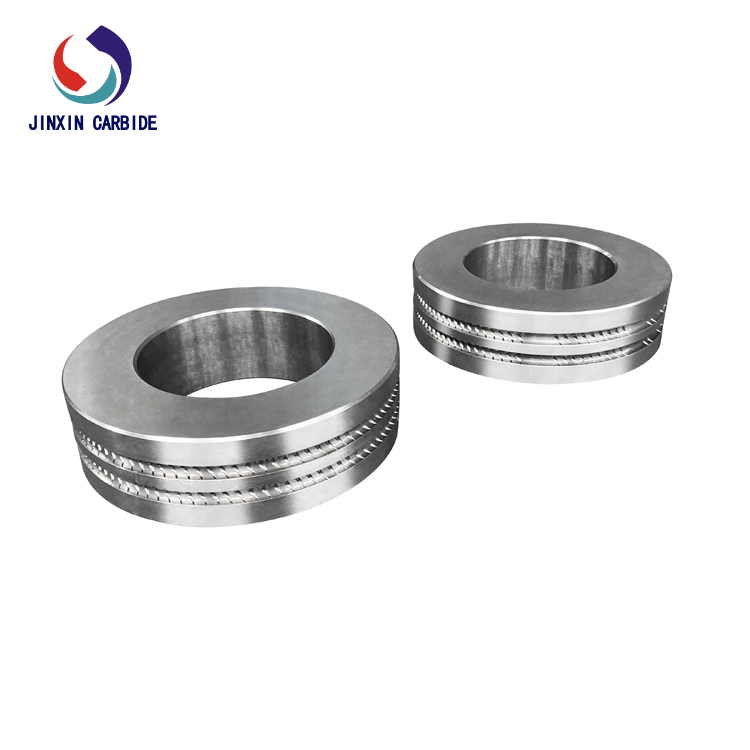

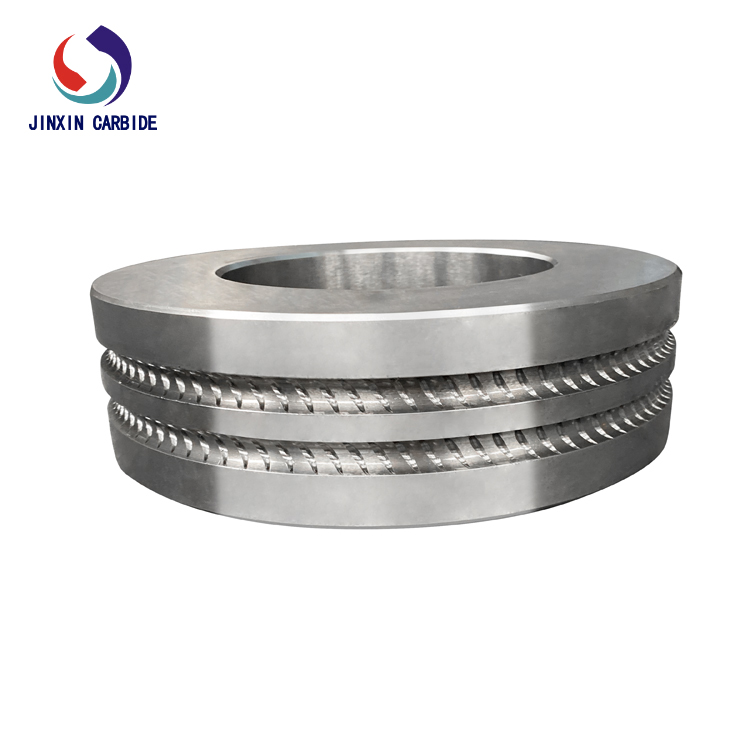

How to Choose Tungsten Carbide Rolls

Choosing carbide rolls requires a comprehensive evaluation of rolling conditions, rolled materials, carbide grades, and other critical factors.

First, it is important to assess the specific rolling parameters, including the material being rolled (such as stainless steel, high-strength steel, copper strip, aluminum strip, etc.), whether the process involves hot or cold rolling, the rolling speed, and whether the roll is used in the roughing or finishing section. Different operating scenarios demand different levels of hardness, toughness, and wear resistance, so a one-size-fits-all approach is not applicable.

The performance of carbide rolls is largely determined by their grades. Common grades such as YG6, YG8, YG15, and YG20 vary in cobalt content and tungsten carbide composition, resulting in differences in hardness, wear resistance, and impact toughness. For instance, YG6 offers high hardness and is ideal for precision cold rolling with tight dimensional tolerances. YG8 provides a balanced combination of wear resistance and toughness, making it a widely used general-purpose option. Grades like YG15 and YG20 offer greater impact resistance, making them suitable for rough rolling, heavy-duty applications, and welded pipe production. When selecting a grade, rolling speed, material thickness, and impact load must all be considered.

Beyond material selection, surface treatment also plays a vital role in roll performance. To enhance heat resistance, anti-adhesion properties, and service life, some high-performance carbide rolls feature PVD coatings such as TiN or TiCN, or undergo high-precision mirror polishing for improved surface finish and rolling stability. Additionally, composite rolls—featuring a carbide outer layer and a high-strength steel core—are gaining popularity due to their cost-effectiveness and stable performance.

Finally, selecting a reliable carbide roll manufacturer is crucial. A supplier with advanced production technology and robust technical support can provide not only consistent product quality but also customized solutions. As a professional supplier of cemented carbide rolls, Jinxin offers tailored grade recommendations based on your specific rolling needs, helping you boost production efficiency, extend roll lifespan, and reduce long-term operating costs.