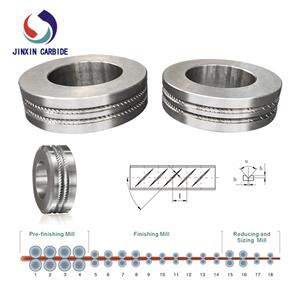

Carbide Roller Cemented Carbide Roll Rings/carbide Roller/tungsten

Brand Name : JINXIN

Place of Origin : CHINA

MOQ : 4pcs

Packaging Details : Case

Delivery Time : 7-15days

Supply Ability : 10 ton/month

Matierial : Tungsten Carbide

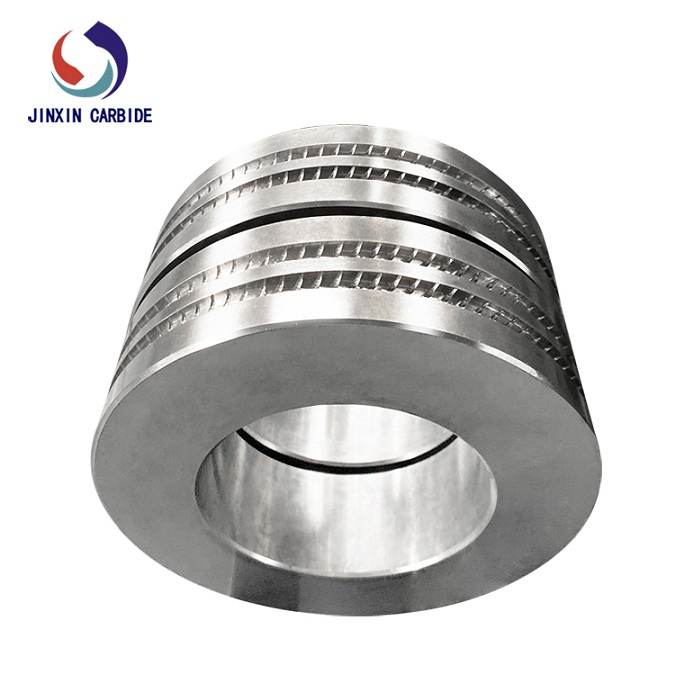

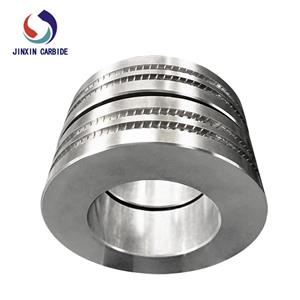

Tungsten carbide roller ring is a kind of metallurgical tool which consists of tungsten carbide and cobalt with high hardness and wear resistance. There are ideal for use in applications where strength, durability and longevity are factors.

Tungsten carbide roller description

Tungsten carbide roller used on the stretch reducing mill for bars, thread steel bars and common wire with the durability 10 to 20 times higher compared to common steel roller. The surface quality and the steel bar size accuracy are greatly improved. The cemented carbide roller reduces effectively the production cost and improves the quality.

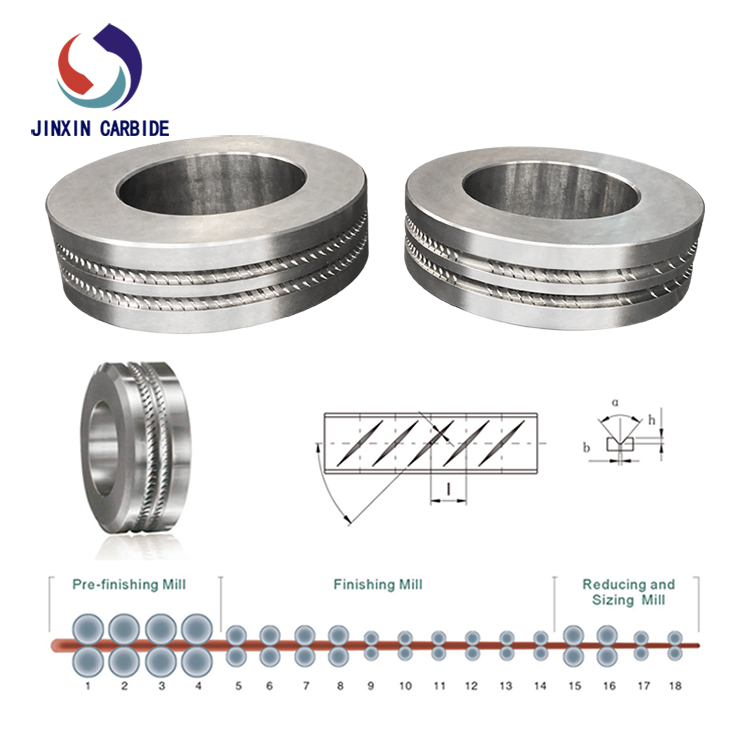

Roller for Profile Wire Rolling, Flat Wire Rolling, Construction Wire Rolling, Plain Wire Rolling and Welding Wire Rolling, Wire Straightening, Wire Guiding etc.

Carbide rollers are widely used in metal forming, especially in hot rolling industry mainly for intermediate and last finishing stands to ensuring superior surface finish and dimensional stability of processed metal products. Rolls are also commonly used for wire flattening, de-scaling and straightening applications.

Jinxin Tungsten carbide roller

Our capacity:

1.Professional manufacturer fortungsten carbide items with more than 10 years experience

2.High hardness and strength

3.High modulus of elasticity

4.Stable chemical property

5.Low impact toughness and thermal expansion coefficient

6.ISO 9001-2008 Quality Control System

7.OEM, ODM project accepted

Tungsten carbide roll production capacity, We can manufacture dimension of tungsten carbide roll below:

OUTER DIAMETER 145-450mm

INNER DIAMETER 87-260mm

HEIGHT 62-130mm

In additional, if you have request of tungsten carbide roll have special requests, we all can discuss with our engneers, we will do the best to match your production requests.

Common material of tungsten carbide rolls:

YGR30, YGR45, YGR55, YGR60, YGH30, YGH40 etc.