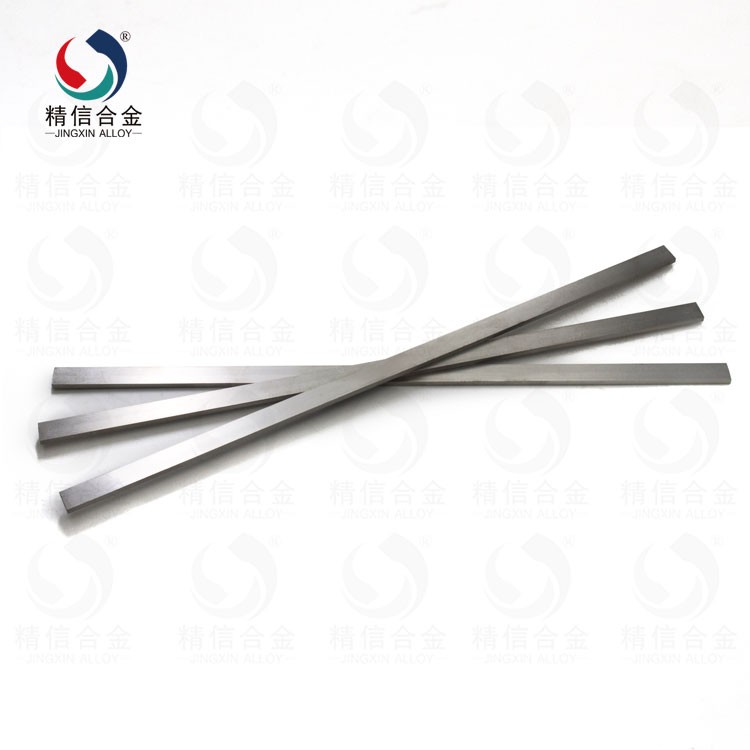

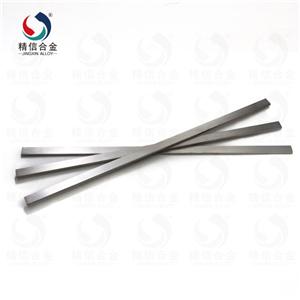

Hard alloy high precision OEM tungsten carbide strips

Brand Name : JINXIN

Place of Origin : CHINA

MOQ : 5kg

Packaging Details : Carton

Delivery Time : 20-30 days

Supply Ability : 1000000kg/month

Matierial : Tungsten carbide

Grade : YG6 YG8 YG10 YG15 YG20 K10 K20 ETC

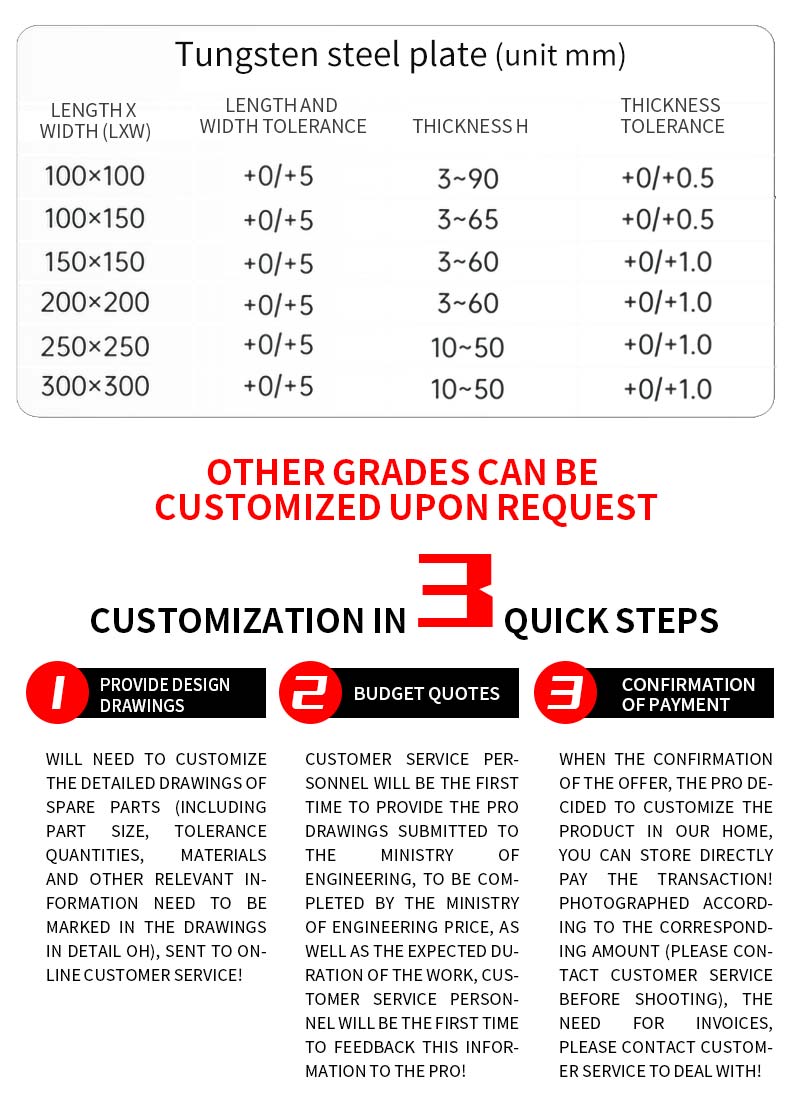

Type : 200*200*5mm

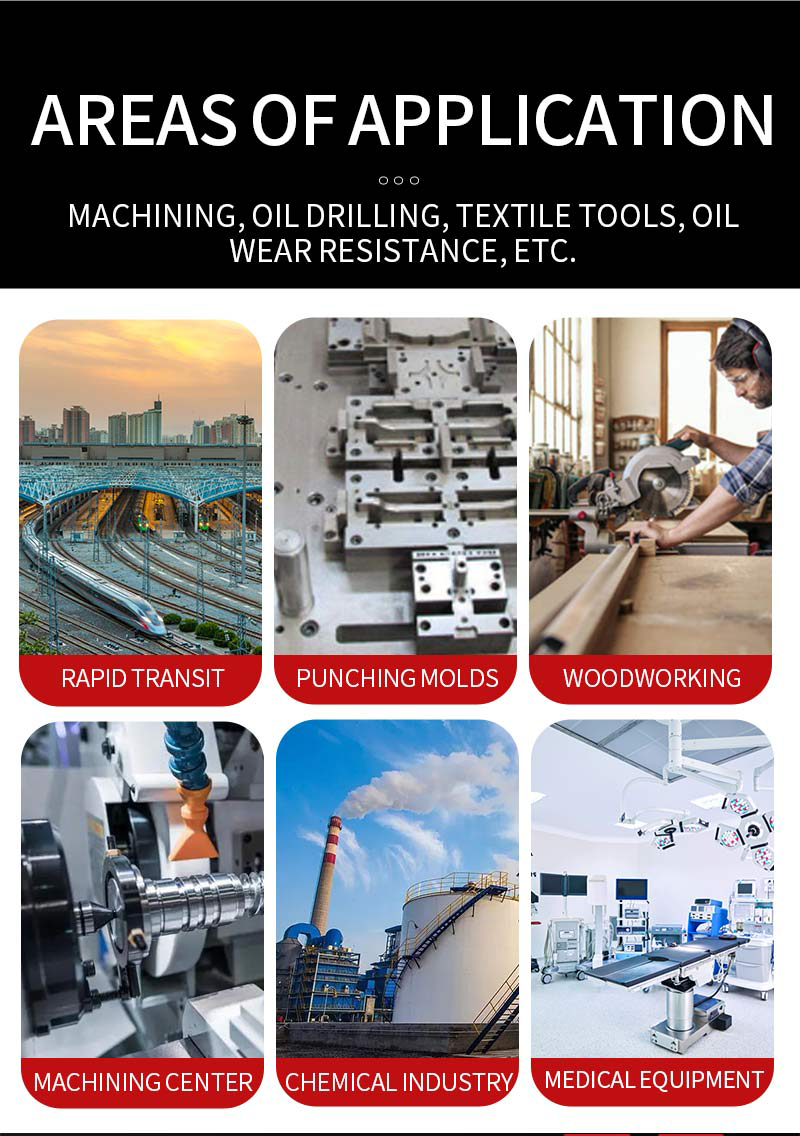

Application : Machining

Grain Size : 0.6um

Our premium tungsten carbide sheets, tungsten carbide strips, and tungsten carbide flat plates are designed for exceptional hardness, wear resistance, and durability in demanding environments. Whether you're seeking individual pieces or wholesale tungsten carbide plate options, our products are ideal for metalworking, woodworking, and mining industries.

Product Description

Our tungsten carbide plates are engineered for superior hardness, wear resistance, and long-term durability. Designed for use in extreme environments, each plate is sintered with precision and finished to tight tolerances, making them ideal for applications like dies, punches, and cutting tools.

Product Application

Precision ground for flatness and dimensional accuracy.

Tight tolerance control for CNC and mold base integration.

Smooth surface finish for improved contact and reduced tool wear.

Perfect for EDM machining, die sinking, and forming dies.

Available in various sizes and thicknesses with consistent quality.

Product Features

Carbide plates are frequently used as base materials for cutting tools, wear parts, and inserts in machining operations. Thanks to their excellent heat resistance and edge retention, they are essential for high-speed machining, metal shaping, and CNC tool bases.

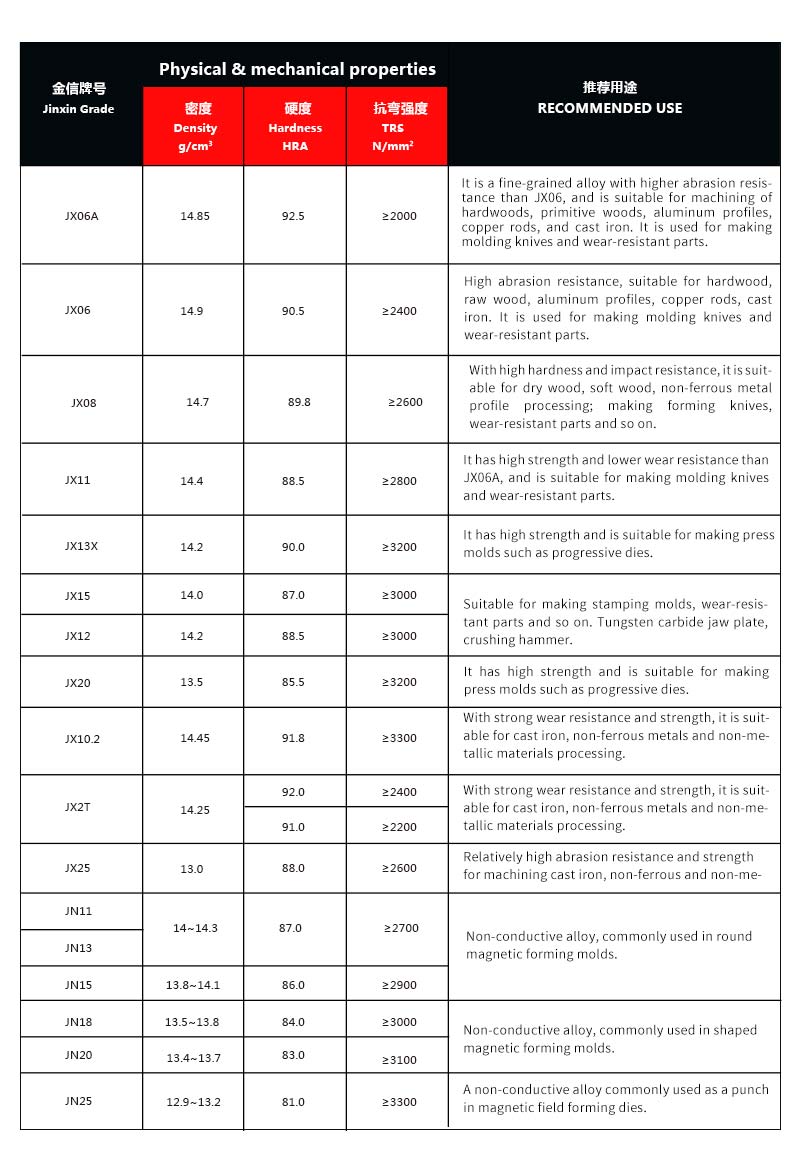

Product Specifications

Grade: YG6X / K10

Grain Size: Sub-micron (0.6 μm)

Hardness: HRA 91–92.5

Tolerance: ±0.01mm (precision grinding)

Flatness: ≤ 0.005mm per 100mm

Surface Roughness: Ra ≤ 0.2 μm

Application: High-speed cutting tools, precision mold bases