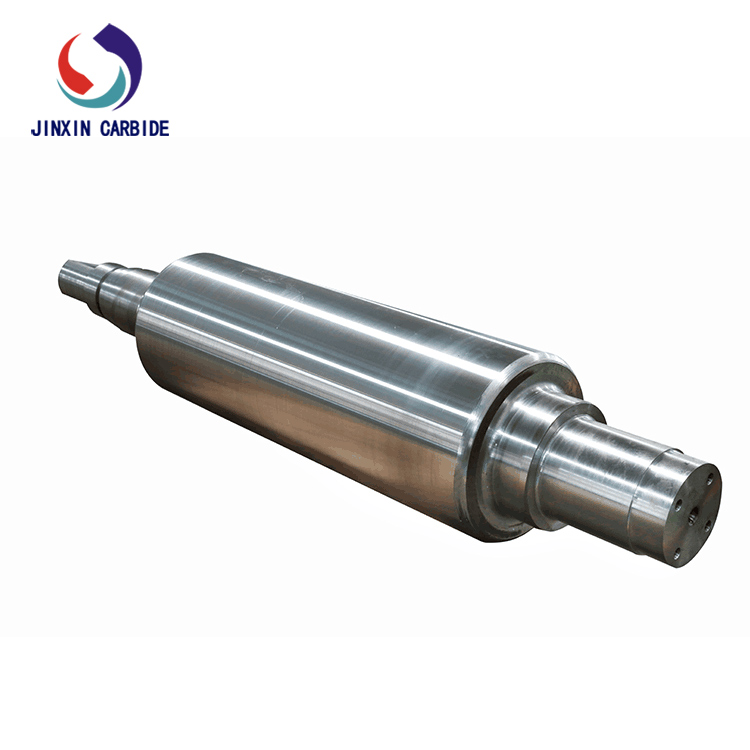

High speed steel rolling ring of tungsten carbide steel roller

Brand Name : JINXIN

Place of Origin : CHINA

MOQ : 5kg

Packaging Details : Carton

Delivery Time : 7-15days

Supply Ability : 10 ton/month

JINXIN with decades' experiences in manufacturing equipment and spares for steel and iron ,we have established good reputation in supply of quality equipment home and abroad.90% of the products of the company with independent intellectual property rights.

1. High-speed steel roll materials contain high alloy elements such as vanadium, tungsten, chromium, molybdenum, niobium, etc. The types of carbides in the roll structure are mainly MC type and M2C type, with high carbide hardness and good wear resistance. Compared with traditional ductile iron rolls and high nickel-chromium rolls, the single groove (time) has a high steel throughput, which saves roll change time, improves mill operation rate, reduces roll consumption, reduces production costs, and improves the overall efficiency of the factory. .

2. The high-speed steel roll has good thermal stability, and the roll surface has high hardness and good wear resistance at the rolling temperature.

3. The high-speed steel roll has good hardenability, and the hardness from the surface of the roll body to the internal hardness of the working layer hardly decreases, thus ensuring that the roll has the same good wear resistance from the outside to the inside.

4. During the use of the high-speed steel roll, under good cooling conditions, a thin and dense oxide film is formed on the surface of the roll body. This uniform, thin and dense oxide film can exist for a long time without falling off, making the high-speed steel roll resistant The grindability is significantly improved.

5. The high-speed steel roll material has a large expansion coefficient and good thermal conductivity. While the roll is abraded with a small amount of groove during the rolling process, the pass is continuously reduced due to the expansion of the high-speed steel material itself. Therefore, the high-speed steel roll is in During the rolling process, the change of the rolling groove is small, and the consistency of the pass size is maintained for a long time, especially when rolling bars or rebars, it is more conducive to control the negative tolerance of the rolling material.

6. Since the core of the centrifugal cast high-speed steel roll is made of alloy ductile iron material, the roll neck has high strength.

◆ Application range of the product

The high-speed steel rolls produced by our company are widely used in:

The finished frame of the bar mill (high-speed steel roll), the front frame of the finished product (high-speed steel roll), the slitting frame (slicing high-speed steel roll), and the pre-cutting slitting frame (slicing high-speed steel roll).

Pre-finishing mill of high-speed wire rod mill. Hot-rolled narrow strip rolling mill finishing mill.

Spring flat steel rolling mill finish rolling stand and angle steel, channel steel and other small section steel rolling mills.