K20 Tungsten Solid Carbide Rod Cermet metal rods

Brand Name : JINXIN

Place of Origin : CHINA

Delivery Time : 7-14DAYS

Supply Ability : 1000000 PCS/MONTH

Matierial : Tungsten carbide、Cermet

Tungsten carbide rods are high-performance industrial materials composed of tungsten carbide and cobalt binder. Known for exceptional hardness (HRA 90+), wear resistance, and high-temperature stability, they maintain strength even at 1000°C.

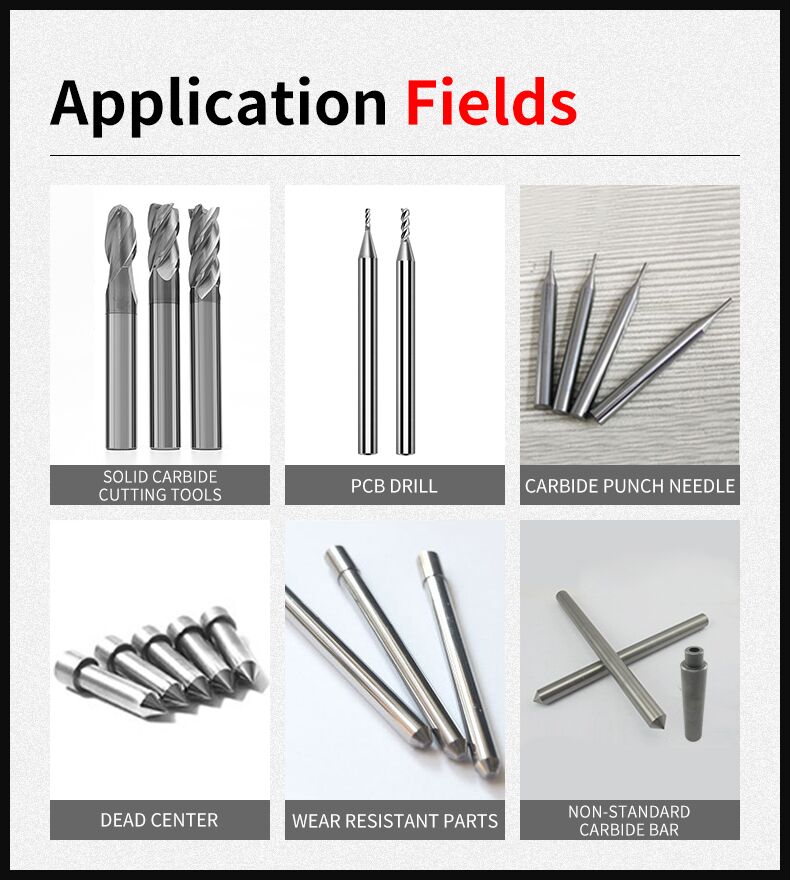

Tungsten carbide rods application

It is commonly used in the manufacture of a variety of high-performance cutting tools, such as milling cutters, drills, engraving knives, etc., suitable for efficient processing of metal, wood, plastics and other materials; in the mold and die industry, tungsten carbide rods can be used to make cold heading dies, cold extrusion molds and other high-precision molds, which significantly enhance the service life of the molds; in the field of machinery manufacturing, it is also commonly used in the production of highly wear-resistant shafts, guides and other mechanical parts, to enhance the operational stability and durability of the equipment.

In the field of machinery manufacturing, it is also commonly used to make highly wear-resistant shafts, guiding parts and other mechanical parts to enhance the operational stability and durability of equipment.

Key advantages include:

Superior durability vs. HSS tools (5-10x lifespan)

Excellent corrosion/oxidation resistance

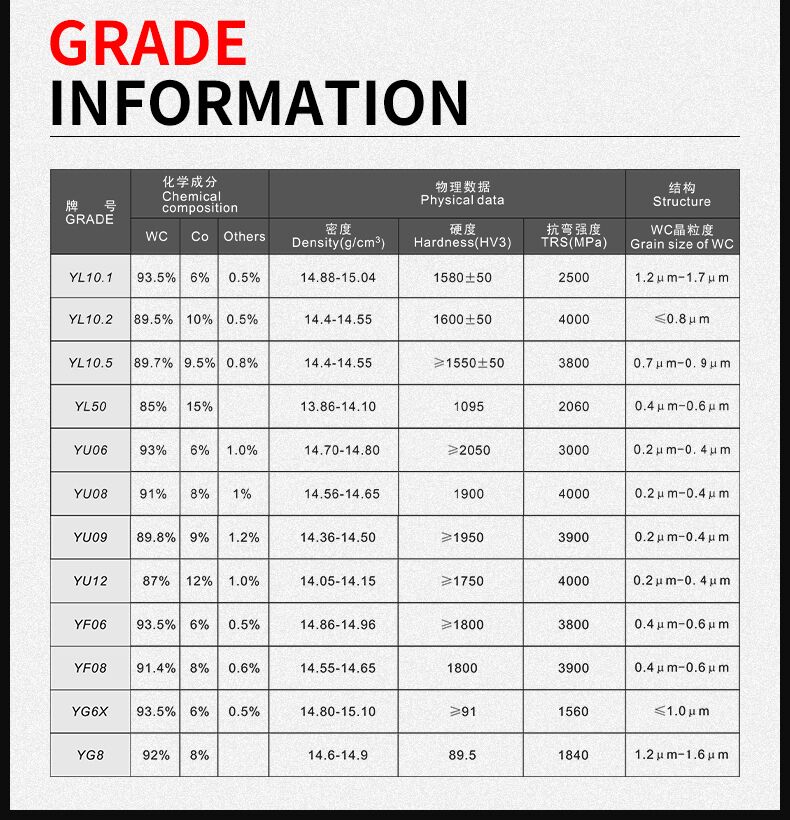

Customizable compositions (6%-20% cobalt content)

Tungsten Solid Carbide Rod characteristics

1. The round bar is produced using a combination of moulding and extrusion techniques.

2. The cemented carbide round bar is sintered by a low-pressure sintering integrated furnace, ensuring optimal performance.

3. The rough tungsten-cobalt carbide round bar, or the outer diameter of the round bar, can be refined and polished according to any tolerance. The common tolerances are h6, h7, -0.005, etc., and the round bar end chamfer can also be processed.

4. The carbide round bar is suitable for the processing of general steel, cast iron, stainless steel, heat resistant steel, nickel base and titanium alloy. It is recommended for general-purpose carbide tool materials, such as twist drills, end mills, taps and gun drills.

Contact:vincent

Mob: +8613357331966

wechat:13357331966

WhatsApp: +8613357331966

Email: jinxin012@ojinxin.com