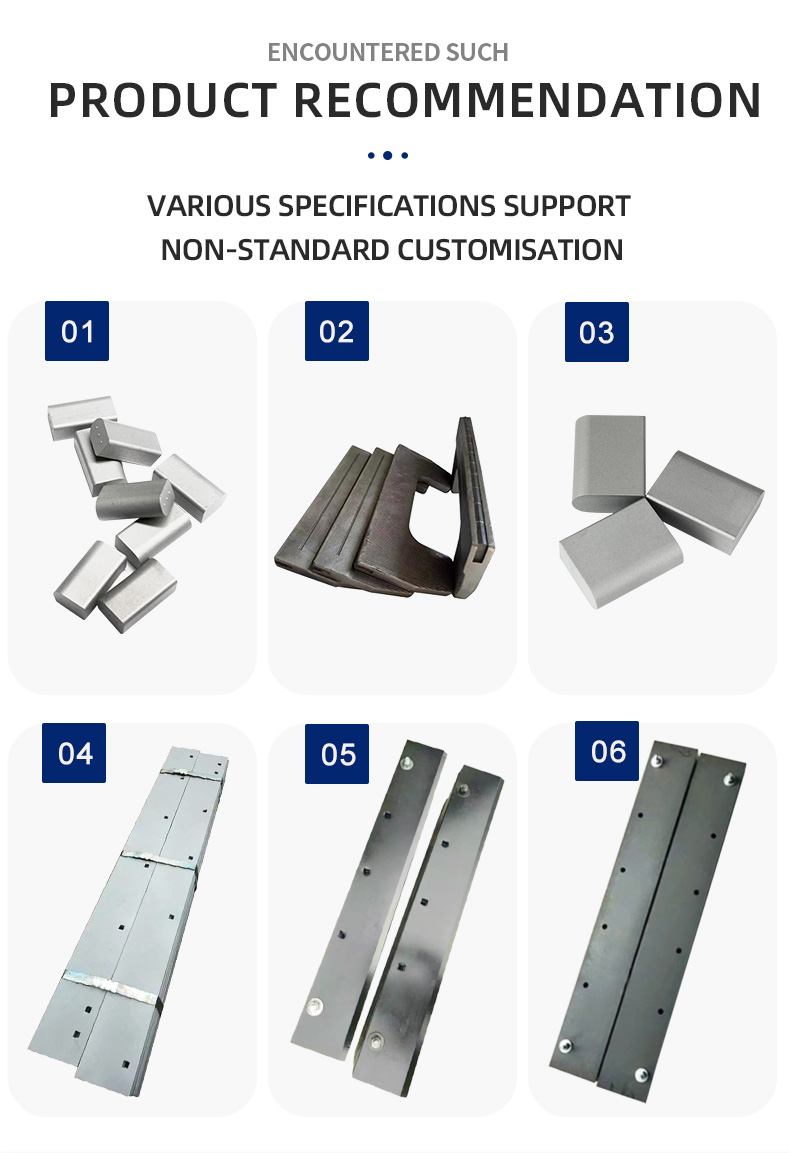

Premium Carbide Tipped Snow Plow Blades for Heavy-Duty Snow Removal

Brand Name : JINXIN

Place of Origin : CHINA

MOQ : 100PCS

Packaging Details : COMMON PACKAGE

Delivery Time : 20-30 days

Supply Ability : 10000 PCS/MONTH

Matierial : Tungsten carbide with steel / rubber

Our premium carbide snow plow blades are engineered for exceptional wear resistance and long service life, ideal for heavy-duty snow removal operations.

Tungsten carbide snow plow blade description

Tungsten carbide snow plow teeth offer superior performance and durability compared to traditional steel blades. While they may be more expensive, the long lifespan and reduced maintenance costs make them a worthwhile investment for snow removal businesses.

Tungsten carbide snow plow blade advantages

Tungsten carbide snow plow blade offer several advantages over traditional steel teeth. They are more durable and last longer, reducing the need for frequent teeth changes. They also provide better traction on icy surfaces, reducing the risk of accidents. Additionally, they require less maintenance, reducing overall maintenance costs.

Snowplow Core Material & Advantages

1. Main Load-Bearing Structure

• Mainstream: High-strength Q235 carbon steel / 65Mn manganese steel

• High-end: 304/201 stainless steel (coastal anti-corrosion)

• Lightweight: Aluminum alloy (small private vehicles)

• High hardness & impact resistance, handles thick/compacted snow

• Hot-dip galvanizing/powder coating for anti-corrosion & long lifespan

• Stable brackets (welded carbon steel) resist snowplowing pressure

2. Bottom Snow Scraper Strip (Wear-Prone Core)

Material: Natural rubber / EPDM

Advantages: Excellent elasticity, no embrittlement, perfect ground adherence, road protection

Material: Polyurethane (PU)

Advantages: 3~5x wear resistance vs rubber, ultra-clean scraping (airports/highways ideal)

3. Auxiliary Accessories

Hinges/Connectors: Galvanized steel/stainless steel – rust-proof, anti-jamming, smooth operation

Buffer Springs: 65Mn manganese steel – obstacle avoidance, automatic reset, high durability

1. Main Load-Bearing Structure

Core Materials: High-strength Q235 carbon steel/65Mn manganese steel (mainstream) | 304/201 stainless steel (coastal anti-corrosion) | Aluminum alloy (lightweight vehicle-mount)

Core Advantages: High hardness & impact resistance, strong load-bearing capacity for easily clearing thick/compacted snow; carbon steel/stainless steel variants with hot-dip galvanizing/powder coating anti-corrosion treatment for long service life; stainless steel for salt-spray coastal areas, aluminum alloy for light snow removal of small private cars.

Brackets & Hydraulic Parts: Welded carbon steel with anti-corrosion coating, stable vehicle connection, high resistance to snowplowing pressure.

2. Bottom Snow Scraper Strip (Wear-Prone Core)

-30℃~-40℃ Extremely Cold Zones: Natural rubber/EPDM – excellent elasticity, no embrittlement, perfect ground adherence

Above -20℃ Normal Zones / High-Frequency Work: PU – 3~5x wear resistance than rubber, ultra-clean snow scraping (ideal for airports/highways)

3. Auxiliary Accessories

Hinges/Connectors: Galvanized steel/stainless steel – rust-proof, anti-jamming, smooth operation

Buffer Springs: 65Mn manganese steel – matched with obstacle avoidance function, automatic reset after encountering obstacles, high durability