wholesale TSS 2mm 2.25mm 2.5mm tungsten super shot

Brand Name : JINXIN

Place of Origin : China

MOQ : 5kg

Packaging Details : Carton

Delivery Time : 3-5 working days

Supply Ability : 1000000kg/month

Matierial : tungsten

Tungsten Sphere has a density of up to 19.25g/cm³, making it one of the highest density options among commercial metals.

Product Description

1.High-density material properties

Tungsten Sphere has a density of up to 19.25g/cm³, making it one of the highest density options among commercial metals. This feature makes tungsten balls widely used in situations that require high-quality counterweights, high inertia or concentrated kinetic energy.

2.Precision machining and high wear resistance

This product uses advanced sintering and precision lathe polishing processes, with a smooth surface and precise dimensional tolerance control (up to ±0.01mm). It has excellent wear resistance and long service life and is suitable for key components in high-precision equipment.

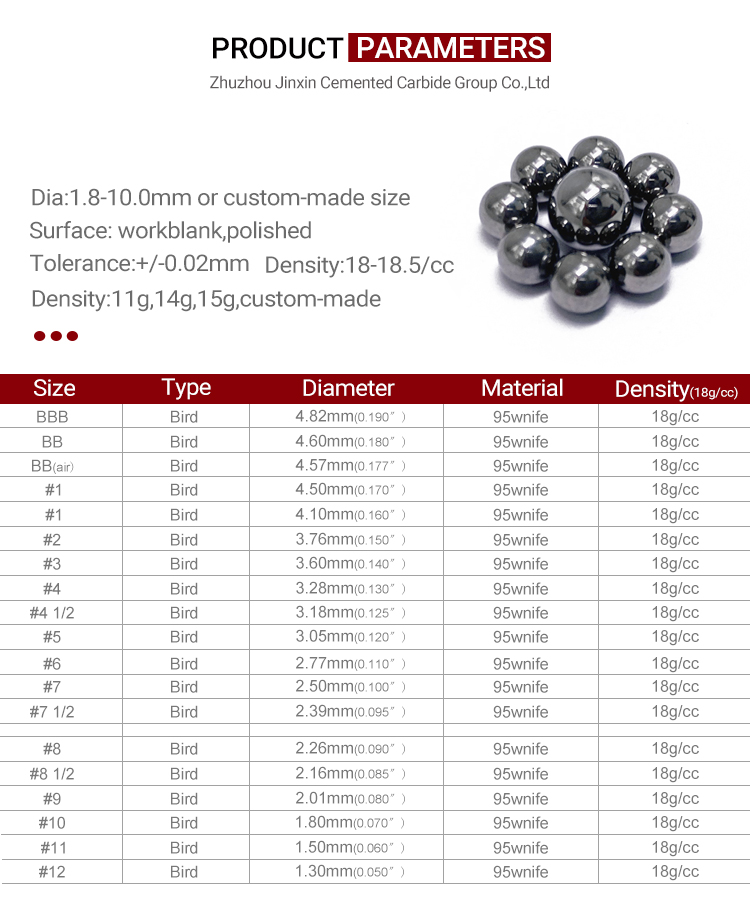

3.Multiple sizes and customized services

Tungsten balls with diameters ranging from 0.5mm to 50mm are available to adapt to different industrial application scenarios. Supports batch customization, packaging customization and material upgrades (pure tungsten/high-density tungsten alloy) to meet diverse needs from scientific research to military industry.

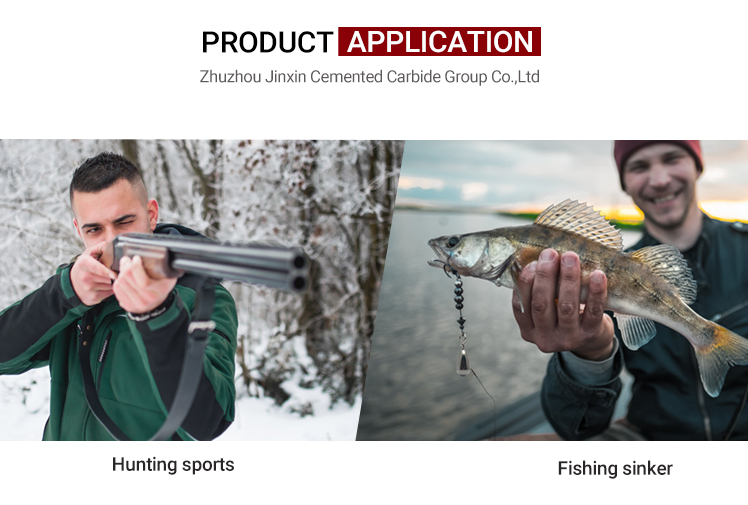

Product Application

1.Aerospace and satellite counterweight systems

Tungsten balls are widely used in satellite inertial modules and aircraft counterweight systems for mass balancing, center of gravity adjustment and orbit control due to their extremely high density and dimensional stability.

2.Defense and ballistic engineering

Tungsten balls are often used to manufacture military ammunition components such as armor-piercing cores and cluster bomb bullet bodies. Due to their high penetration and strong kinetic energy transfer performance, they have become one of the important materials for modern military technology.

Product Feature

* High radiation adsorption capability;* High impact resistance and crack resistance;

* High ultimate tensile strength;

* High temperature resistance;

* Deep Processing property significantly increased;

* Weldability and oxidation resistance greatly enhanced;

* Yield increase and cost reduction;

* A certain Magnetic;

* Superior wearing resistance;

* Non-toxic and environmental friendly.