Tungsten carbide rotary burr SF-5 Double Cut

Brand Name : JINXIN

Place of Origin : CHINA

Delivery Time : 7-15DAYS

Supply Ability : 10 ton/month

Matierial : Tungsten carbide,tungsten

Tungsten carbide burrs are mainly used for cutting and processing all kinds of metal work-pieces and polishing welded metal parts as well as non-metallic handicrafts like marbles, jades, and bones, and also for medical-surgical cutting equipment. As a necessary tool for bench workers and repairmen, its advantages are good cutting quality, smooth finish of work pieces and long tool service lifetime, which ensures better production efficiency and economic benefits in comparison to similar products.

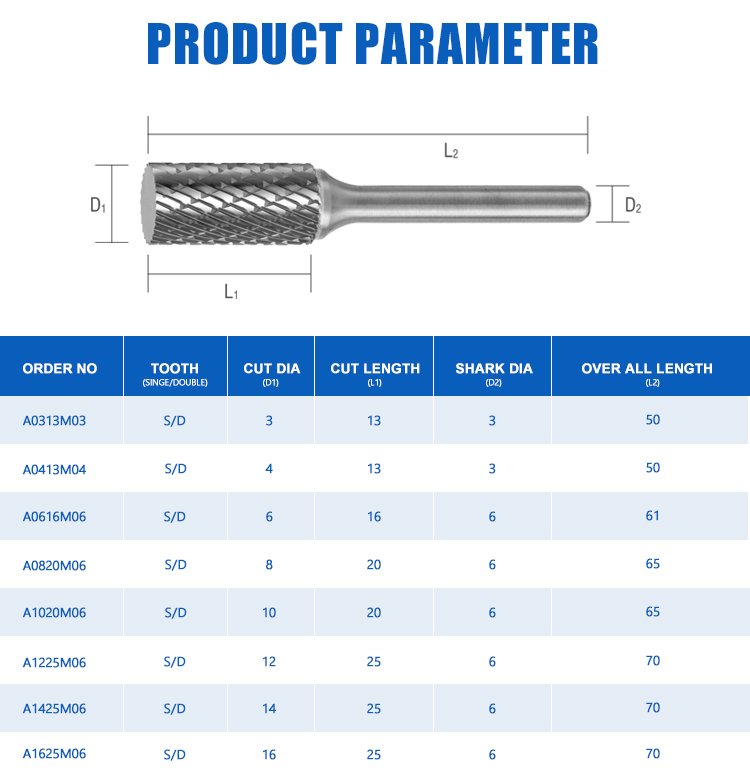

Product Description

Multi Purpose: Widely used for metalwork, tool making, engineering, model engineering, wood carving, jewellery making, welding, chamferring, casting, deburring, grinding, Tree Shape Radius End head porting and sculpting

Good Quality:Good processing quality, high finish. Can be processed into a variety of high-precision shape mold cavity

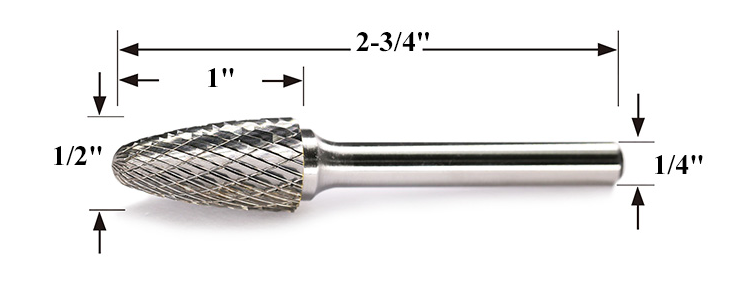

Shape:Double cut Tree Shape Radius End shape SF-5, Size: 2 3/4" Total length, 1/4" shank diameter, 1/2" cutter diameter, 1" length of cut

Long Life: Made of heat-treated Solid tungsten carbide YG8 that lasts 8 times working life Durability than HSS tool,Suitable for machining various kinds of metal material including ≤HRC65 hardened steel

Packaging:Packed with a transparent plastic tube for safety storage and protection

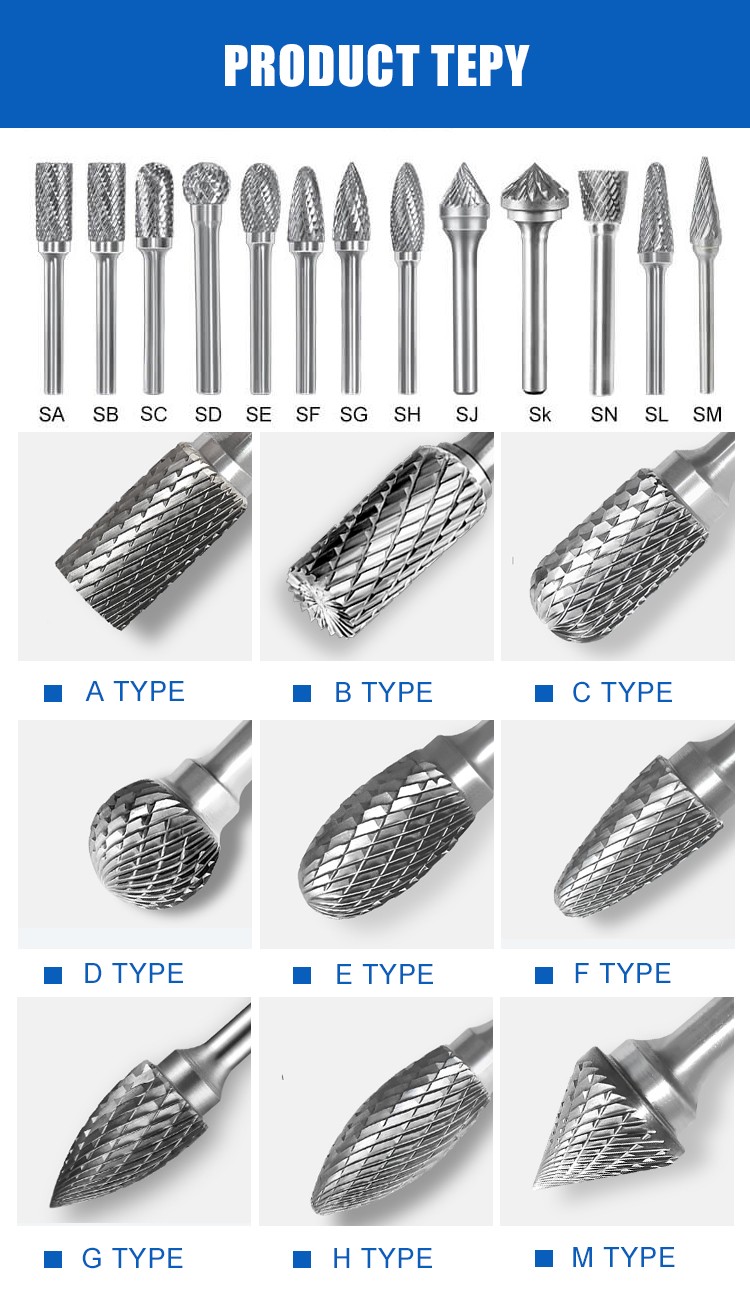

F-SHAPE

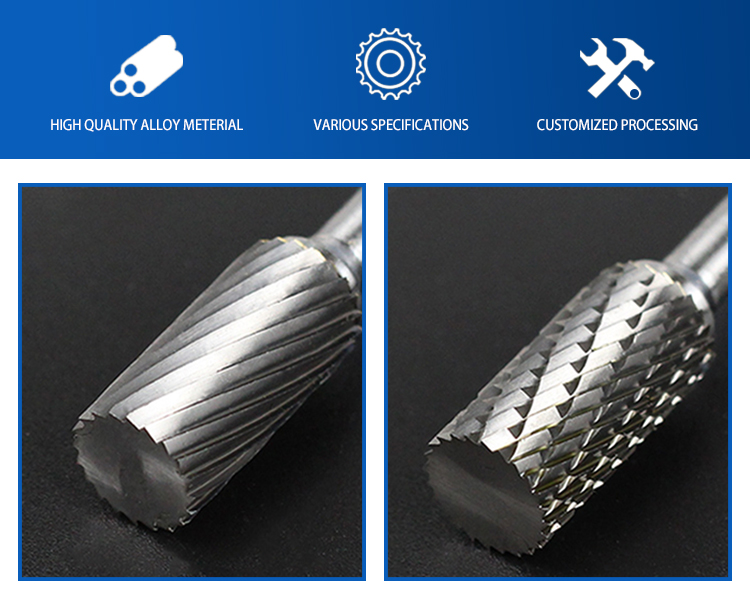

Manufacturing Features:

Carbide burrs produced in CNC FULLY GROUDING, Tolerance controlled at .005-.001mm

Made from Tungsten Carbide K20 Micrograin (hardness >90 HRC). Solid up to Ø 6 mm;

with steel shank welded to the burr startin from Ø 8 mm.

Sizes of the sha 6x40 mm or 6x100 mm (Long Series).

Nine different cut are available (Standard Single,Fine Single, Coarse cutter, Chip Breaker, Double-Cut(Cross)

Coarse Double-cut,Fine Double-Cut, Diamond Cut, Non-Ferrous-Aluminium Cut).

All the burrs are available also with a Titanium Nitride coating (TiN), that makes them tougher reduces surface

friction or with Titanium Nitride and Aluminium coating (TiAlN), that makes the burrs frictionless and prevents binding.

we recommend to careful choose the cut of the burrs, according to the material to be worked.

Advantages:

1. Material: 100% virgin raw material with submicron grain size;

2. Grade: Various grades for choice;

3. Advanced production equipments and testing equipments

4. Precision Ground and polished;

5. High wear resistance,high hardness and impact toughness;

6. Samples & small orders are acceptable.