How to Choose the Right Tungsten Carbide Roll for Your Rolling Mill?

In the modern metal processing and material forming industry, tungsten carbide rolls (Tungsten Carbide Rollers) are widely used in the precision rolling of steel, copper, aluminum, wire rod and other products because of their excellent wear resistance, high hardness and long life.

To choose the right tungsten carbide rolls for the rolling mill, firstly, we need to choose the matching tungsten carbide rolls according to the actual working conditions.

For example: three-roll mill, commonly used in cold rolling of steel bars, alloy wire rod, recommended tungsten carbide ring type rolls;

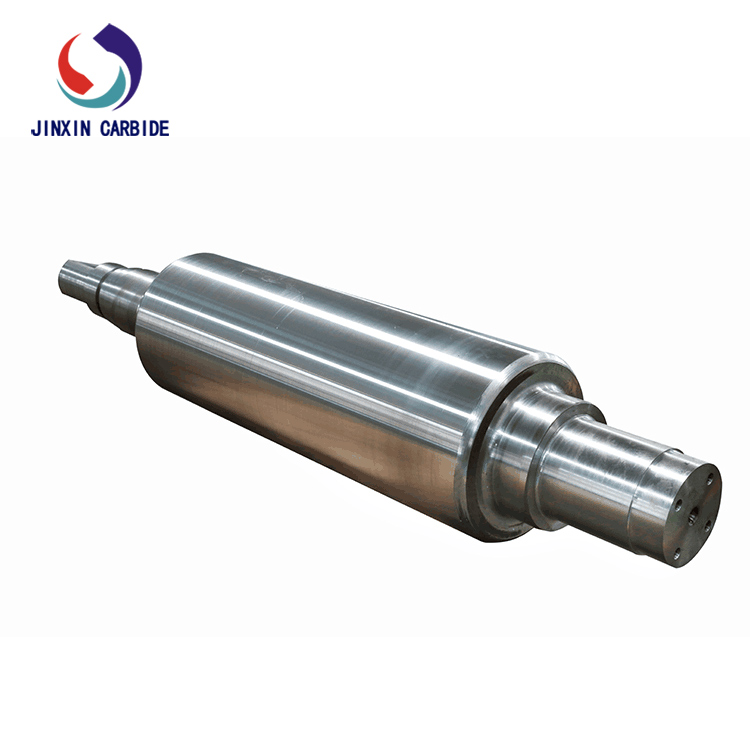

Double-roll mill, commonly used for copper bars, aluminum wire, profiles, recommended integral tungsten carbide rolls or inlaid rolls;

Finishing mill unit, commonly used in high-precision size control, recommended mirror tungsten carbide rolls or composite rolls.

Although the initial cost of cemented carbide rolls is higher than ordinary alloy steel rolls, but its life is 5 to 10 times that of ordinary rolls.

Different hardness of tungsten carbide rolls can be selected for different processing materials: HRA 86~88 for plain carbon steel/copper and aluminum, HRA 89~91 for alloy steel/stainless steel and HRA 91~92 for high speed wire rod/cold rolled strip.

Of course, you can also directly come to consult Jinxin's experts to help you propose a suitable program.