How tungsten carbide balls are used in bearings

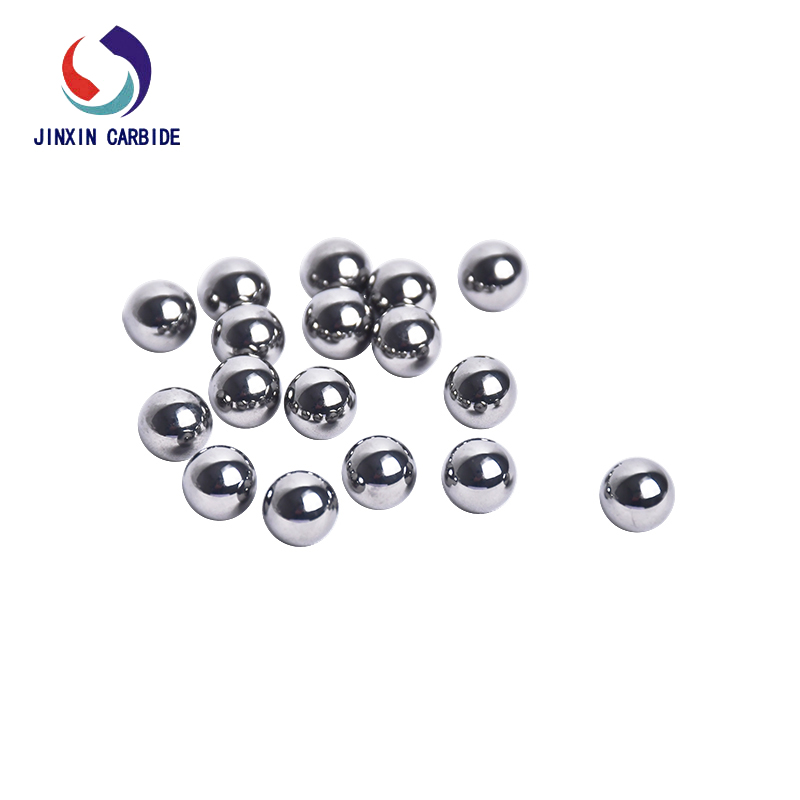

In modern industrial applications, the performance of bearings determines the stability and life of the entire mechanical system. In order to meet the demands of high loads, high speeds and extreme environments, more and more engineers are choosing to use Tungsten Carbide Balls as the core rolling element of bearings.

In high-speed rotating equipment, tungsten carbide balls can reduce vibration and oscillation due to their high density and good centrifugal stability, which improves the operating efficiency of the whole machine. Compared with ordinary steel balls, tungsten carbide balls are more wear-resistant and less susceptible to fatigue spalling, and can maintain stable operation for a long time in high-frequency rolling, which significantly prolongs the maintenance cycle of bearings.

Tungsten carbide bearing balls are mainly used in the following industries:

Aerospace field: used in inertial navigation system, high-speed gyro to maintain rotational stability.

High-end automobile manufacturing: used in engine bearings, turbocharging systems and other high-temperature parts.

Machine tools and industrial automation equipment: to ensure long-term smooth operation of the transmission system.

Pump and valve systems: Provide high sealing and impact resistance in hydraulic pumps and high-pressure valves.To know more about tungsten carbide ball products specifically you can contact Jinxin experts to help you.