Pump wear plate cutting ring material and classification

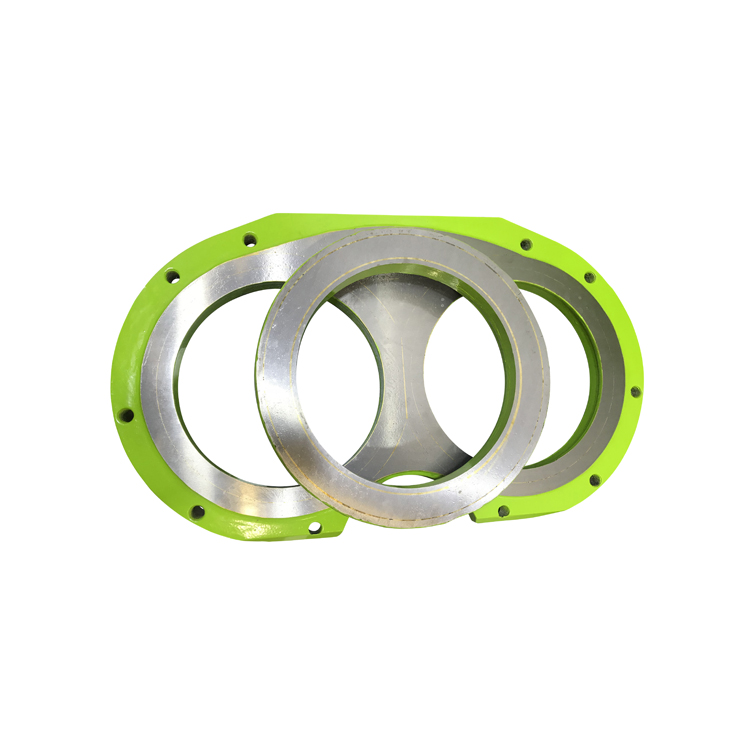

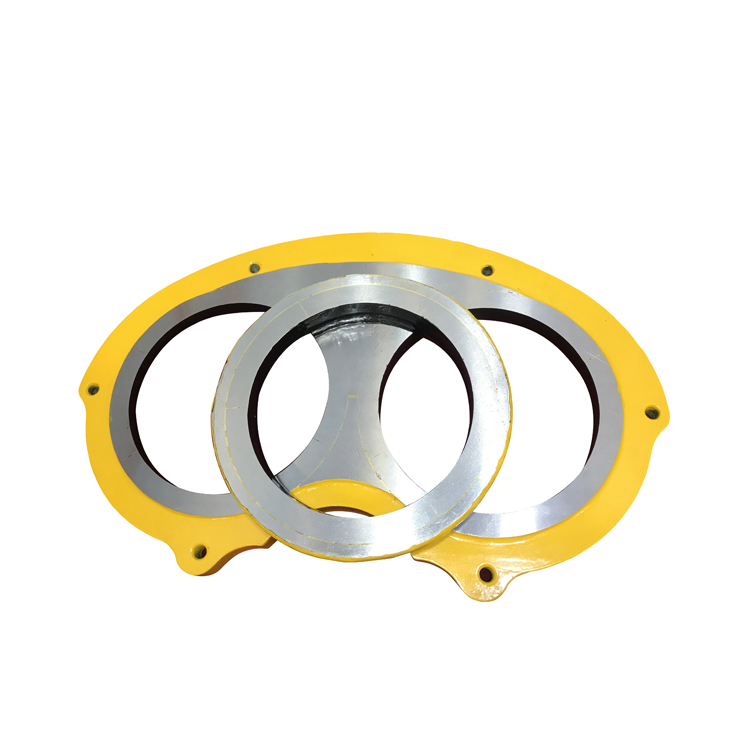

Wear plate, also known as spectacle plate, is a key component in concrete pump trucks. Its shape is similar to a spectacle plate, hence the name. The wear plate mainly withstands the abrasion and impact of concrete during the pumping process and protects the pumping system from damage.

Commonly used wear plate materials include high chromium alloy cast iron, tungsten carbide, cemented carbide and alloy ceramics. These materials have high wear resistance and hardness, and can adapt to the harsh working conditions of concrete pumping.

Cutting ring, also known as wear-resistant ring, is another important part used in conjunction with wear-resistant plate in concrete pump truck. Its shape is in the shape of a circle, in the working condition to do shear movement, the concrete will be cut and pushed to the conveying pipe.

Similar to the wear plate, the cutting ring is often made of high chromium alloy cast iron, tungsten carbide, tungsten carbide and alloy ceramics. These materials are not only wear-resistant, but also have high strength and toughness, which can meet the working requirements of the cutting ring in the pumping process.

Pump wear plate cutting ring can be divided into the following categories:

High chromium alloy cast iron class: with high wear resistance and toughness, suitable for concrete pumping under general working conditions.

Tungsten carbide class: extremely high hardness, excellent wear resistance, suitable for concrete pumping under high hardness and high wear conditions.

Cemented carbide: combining the advantages of high hardness and good toughness, suitable for occasions requiring high wear resistance.

Alloy ceramics: very high hardness and wear resistance, but the price is higher, suitable for pumping efficiency and quality of the occasion has very high requirements.