The role and characteristics of tungsten carbide round rods for PCB

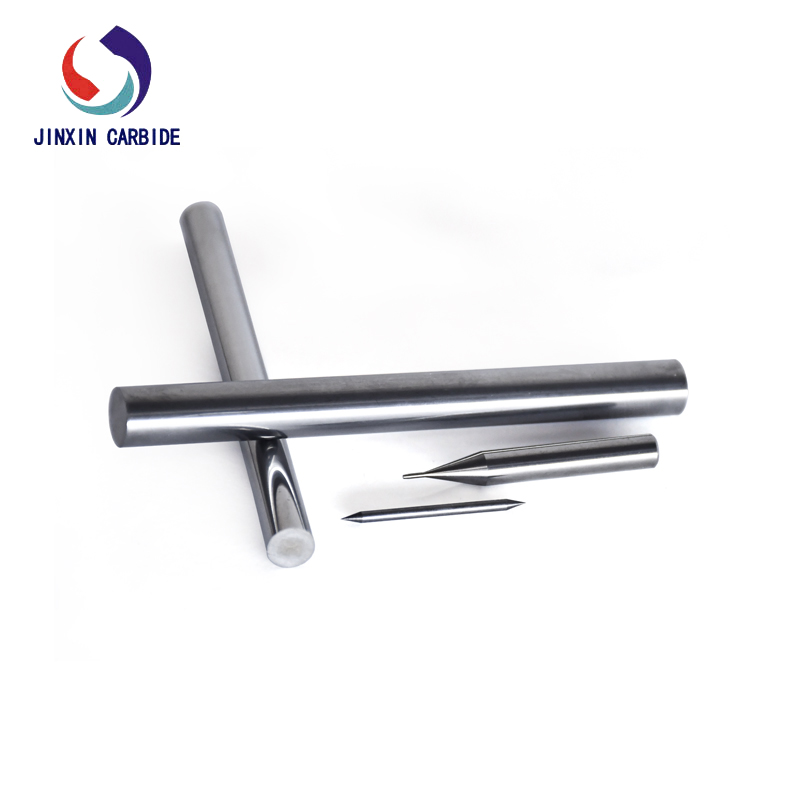

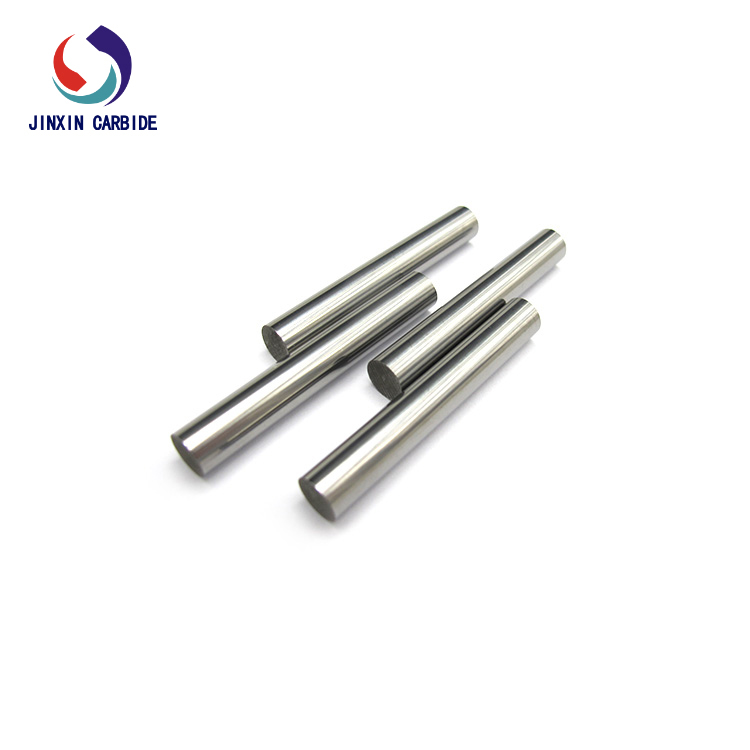

Cemented Carbide Round Bar is a very durable and extremely hard tooling material that is widely used for a variety of precision and wear-resistant tasks. Tungsten carbide round rods also have their specific applications in the manufacturing and repair of PCB (Printed Circuit Boards).

Cleaning solder joints: used to remove solder and slag from soldered areas, as its high hardness effectively removes residues without damaging the PCB.

Contaminant removal: Tungsten carbide round bars can be used to remove contaminants and impurities from the PCB surface.

Precision Adjustment: Used for precision adjustment and alignment of components on PCB, carbide round rods provide accurate operation.

Component Alignment: When mounting and aligning PCB components, Carbide Rods can help to ensure that the components are positioned and aligned accurately.

Cutting and Drilling: When PCB need to be cut or drilled, carbide round rods can be used as a processing tool, especially when working with hard materials.