what is tungsten carbide plate used for?

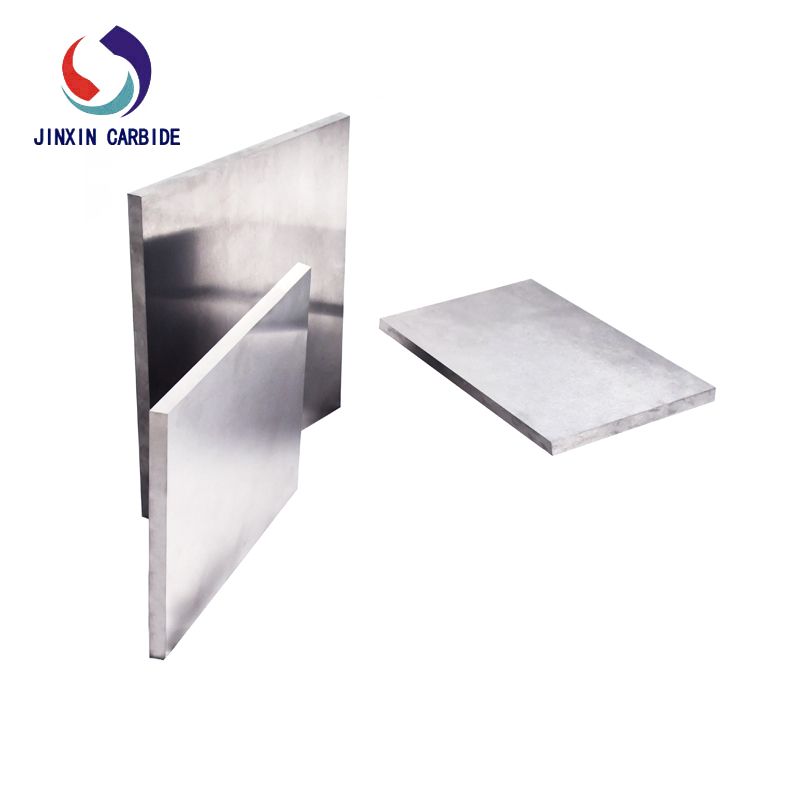

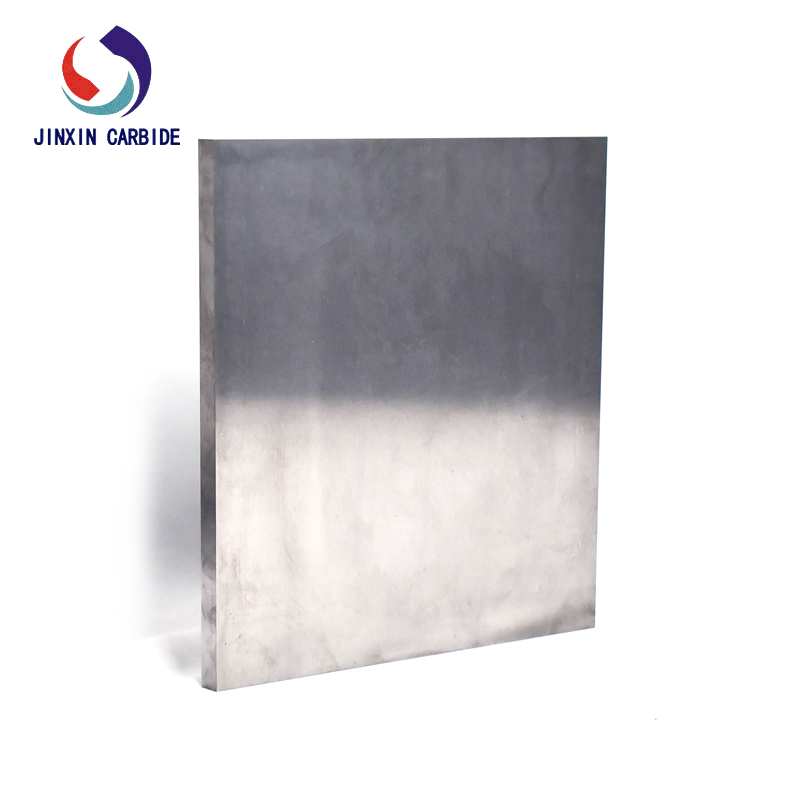

As we all know, tungsten carbide plate is an alloy material made from tungsten carbide combined with other binder metals, sintered at high temperatures to form a high-hardness, high-density composite. Its hardness is second only to diamond, making it an indispensable material across many industrial sectors. Let’s take a closer look at some of its key applications.

The mold industry is arguably the primary market for tungsten carbide plates. Common tools such as cold stamping dies, drawing dies, press dies, and even punches used in core mold components are often made from tungsten carbide. Compared with traditional mold steel, tungsten carbide plates offer a major advantage in durability — they maintain their shape and resist wear even under continuous stamping and heavy-load conditions.

In metalworking, tungsten carbide plates are widely used to produce the cutting heads or core components of various tools, including turning tools, milling cutters, cut-off tools, and other forming tools used in CNC machining. Metal cutting typically involves high temperatures and speeds, which can easily cause ordinary materials to chip or lose their edge. In contrast, tungsten carbide plates can withstand extreme heat and pressure while maintaining sharpness and stability.

In industries such as mining, metallurgy, and steelmaking, many machine parts are subject to constant friction and impact — for example, liners, sliders, support blocks, and cutting edges. Tungsten carbide plates are ideal for these components, providing excellent wear resistance and impact strength that prevent premature part failure even in harsh environments.

Different applications require different grades of tungsten carbide plate. For example, YG6 is suitable for stamping dies, YG8 is preferred for wear-resistant parts, and the YW series works well for cutting tools. For operations involving high impact, elevated temperatures, or corrosive conditions, materials with higher toughness and more wear-resistant coatings are recommended. Plate thickness, tolerance, and surface finish can also be tailored based on the machining drawings.

If you're unsure which grade to choose, feel free to contact Jinxin for expert recommendations and customized solutions.